How Does the AirSweep System Work?

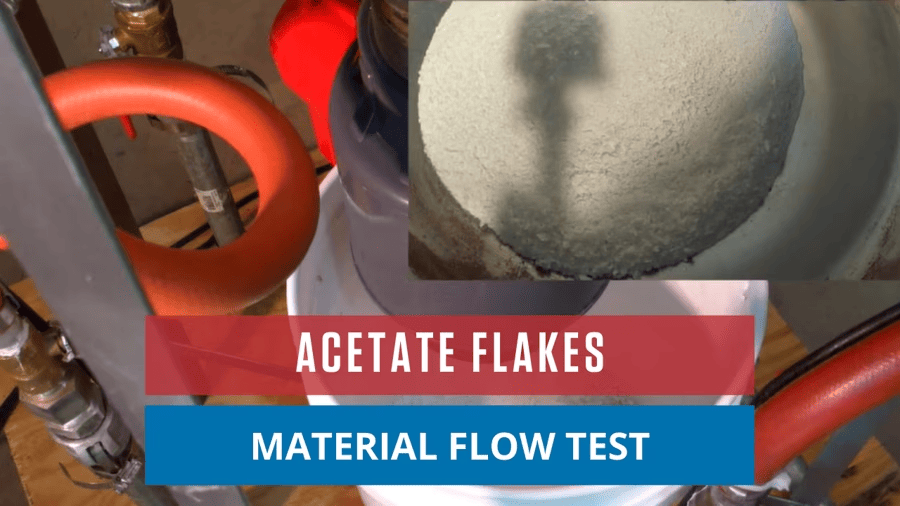

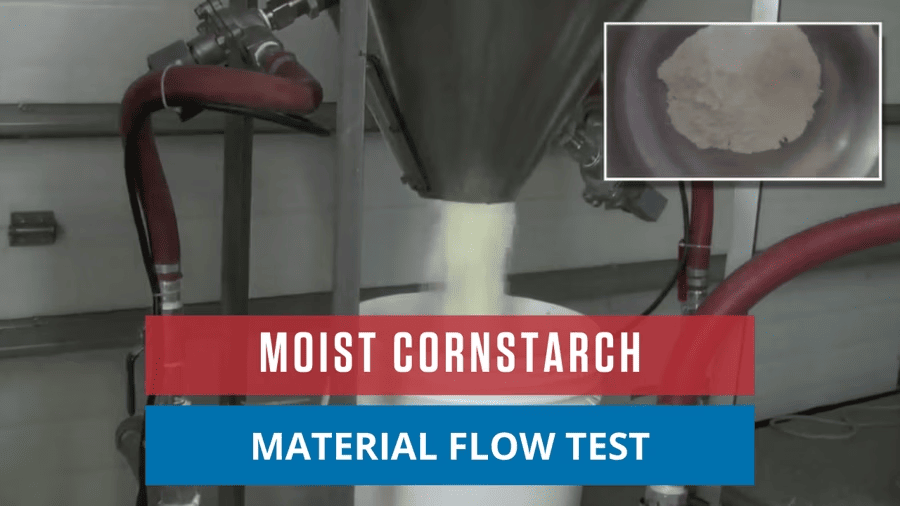

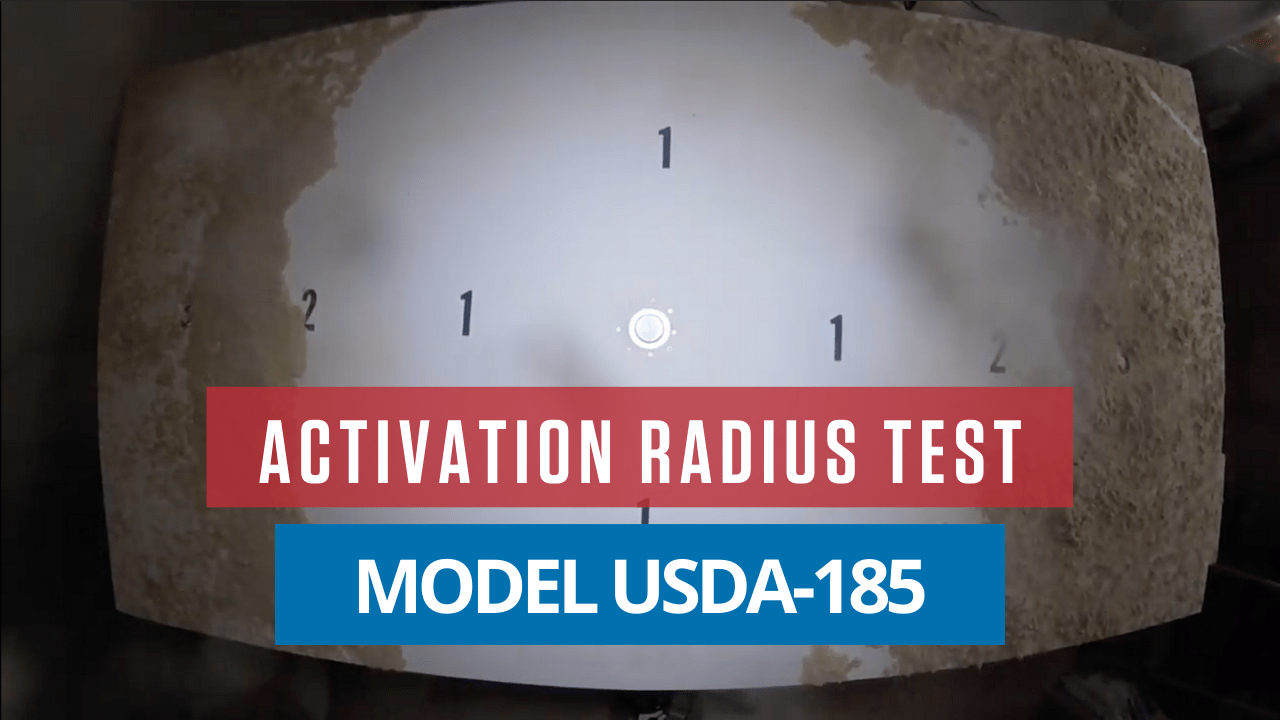

The AirSweep system prevents bridging, ratholing, arching, and other material flow issues. The powerful nozzles release high-pressure, high-volume, 360-degree bursts of compressed air. These break up material blocks, and sweeps stalled material back into the flow stream.

But how does the AirSweep system really work? This video explains the typical AirSweep system. You will see:

AirSweep components

Look at the parts, what they do, and how they work together to slice through the toughest bulk materials in seconds.

AirSweep installation

The 3D model shows how AirSweeps are positioned on a vessel like silo, bin and hopper. The air pulses are perfectly timed for a first-in, first-out on-demand material flow.

AirSweep efficiency

By the end of the video, you will see why the AirSweep system is especially designed to handle any kind of material—from fine powders to bulk solids.

AirSweep proves that bursts of air, sent at the right place and the right time, can guarantee smooth material flow and higher factory efficiency.