Fix Bin Rash with AirSweep® Floweze

Poor material flow can stall your production line, and eventually, your company’s profits. Studies show that 80% of storage vessels don’t operate at capacity because they can’t move the material fast enough. Workers resort to hammering the bins, but that “solution” creates a whole new set of problems. You damage the vessel, waste skilled labor, and put yourself at legal risk for any injuries that can happen while they manually clean and declog your vessels. The smarter solution: AirSweep Floweze.

What is AirSweep?

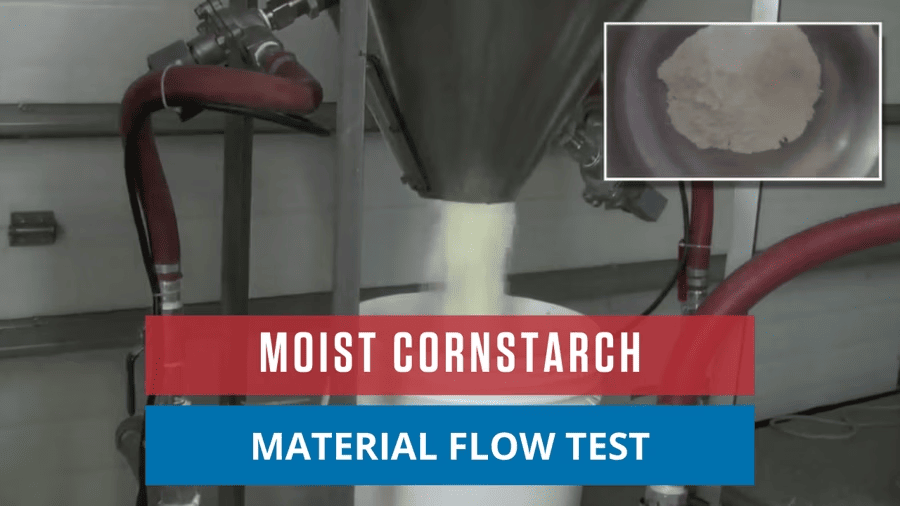

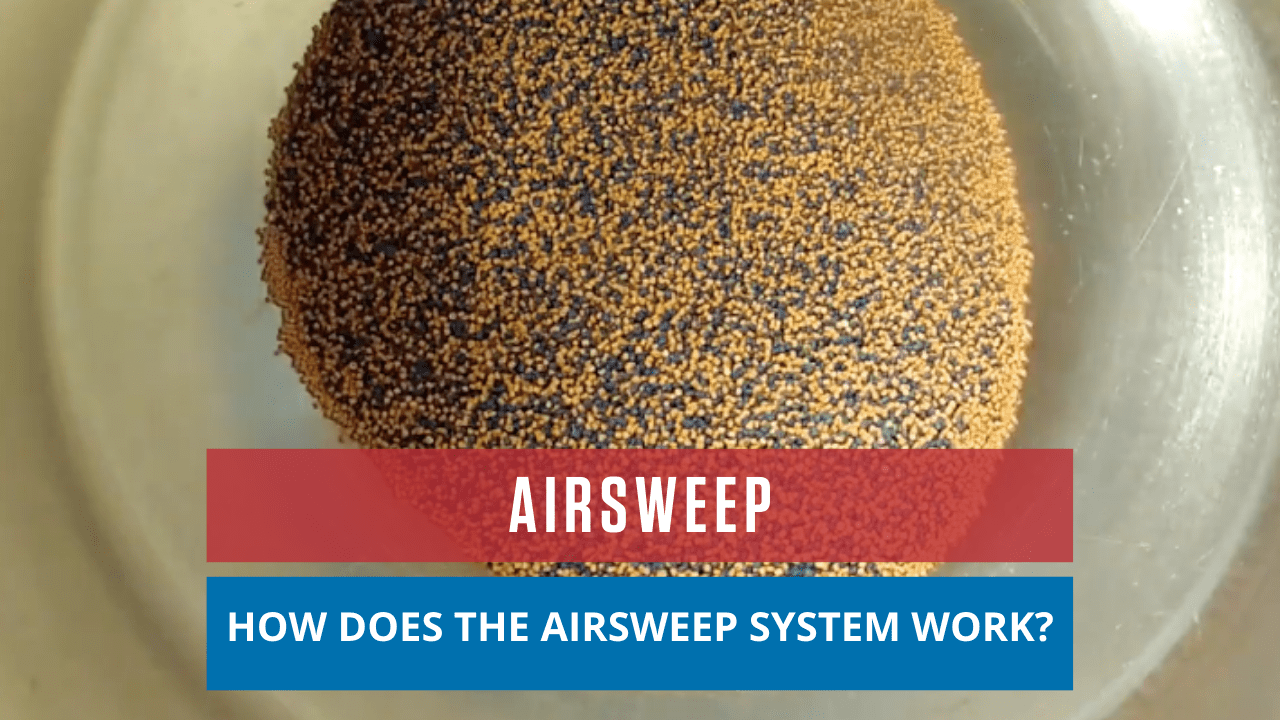

AirSweep is a material activation system that uses high-pressure air to cut through blocks and dislodge materials that cling to vessel walls. Think of it as an air knife. The powerful, strategically placed nozzles direct powerful blasts of air in a sequence that’s customized to your material and process. In seconds, your vessel is completely flushed clean and ready for your next batch. No hammering, no damage or delays, no contamination. Your material (and your production process) flows with ease.

That’s the Floweze magic.

Watch how the AirSweep material activation system blasts through ratholing, bridging, and clogging. It’s amazing how a simple blast of air, delivered at the right place and at the right time, can keep your material flowing and your process on track.