AirSweep: Dust-Tight Design, Easy Maintenance!

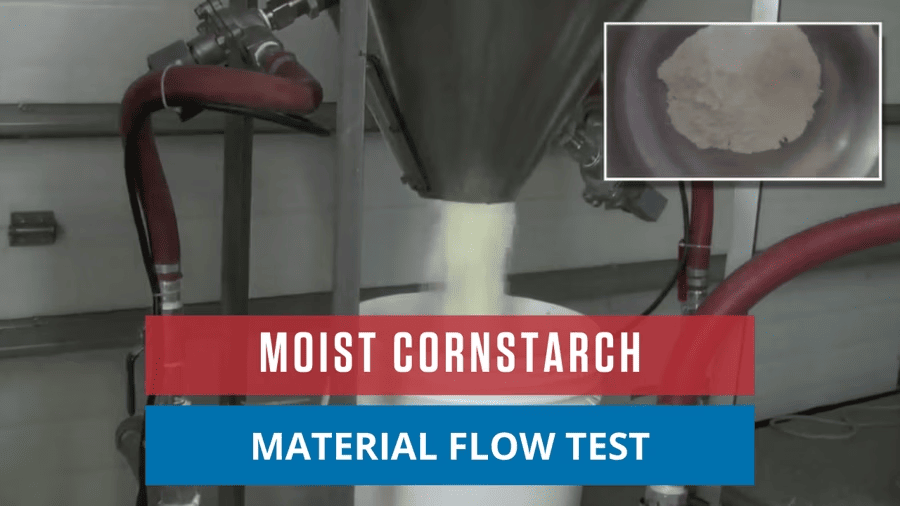

How much time and money do you lose every month because you need to shut down your production to clean your flow aid systems? That’s a common issue with most pneumatic flow aids. The material gets trapped in the material activation device, compromising performance and even causing cross-contamination.

Material Feedback—It’s a Money Issue!

Every time you pause production to clean out your flow aids, you lose time and money. Aside from lowering your output, you have to assign someone to dismantle the equipment, and manually remove any trapped debris.

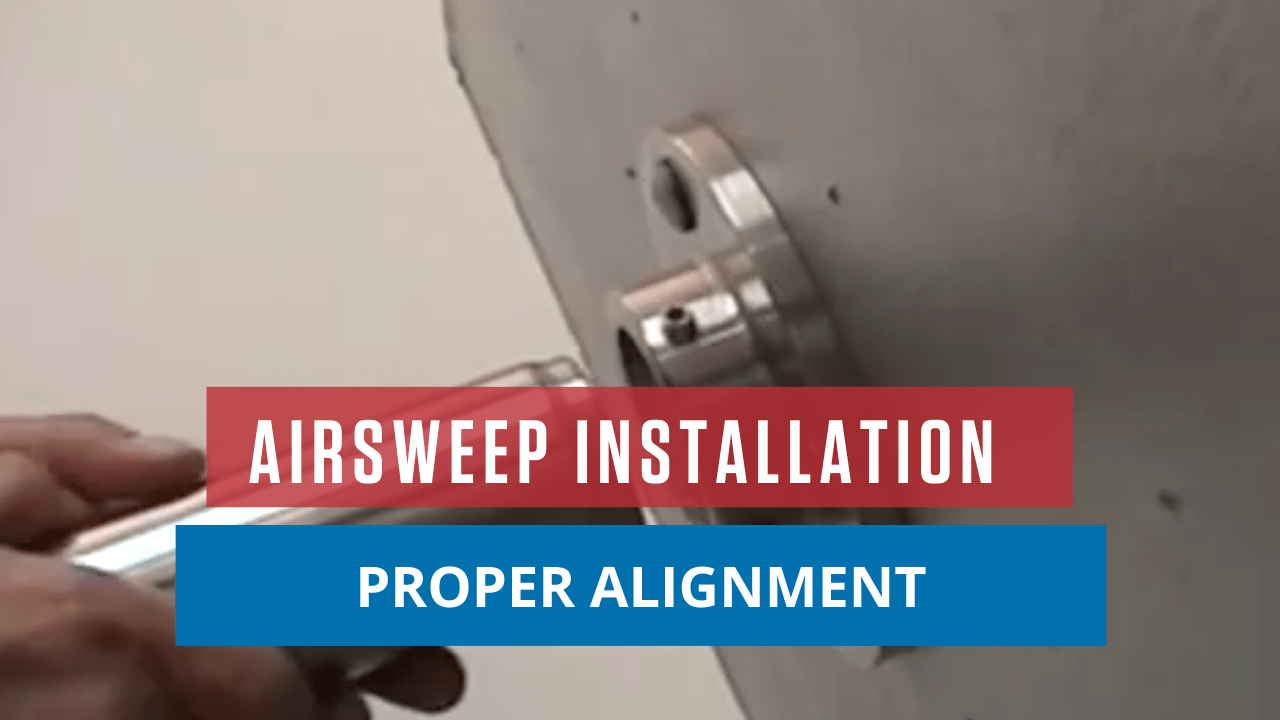

That’s never a problem with the AirSweep system. It is designed to be completely dust-tight, so material never enters its individual parts. The patented nozzle design closes shut after each pulse, and is locked in place by a heavy-duty compression swing when it’s not in use. You have zero material feedback.

Watch proof of AirSweep’s dust-tight design

We submerge an AirSweep nozzle to see if water will leak through to the nozzle and solenoid valves. Will the AirSweep system stay dry and clean? See the results yourself.