Spent Grain Material Flow Test

Spent brewer’s grain is a by-product from mixing barley malt and other cereals or grains for making wort or beer. Since it has a lot of protein and fiber, the spent grains are dried and sold as animal feed.

The wet mixture of malt and grains is very dense and glutinous. It has a tendency to stick to vessel walls or form large clumps.

Spent brewer’s grain poor flow properties can be seen in this material flow test.

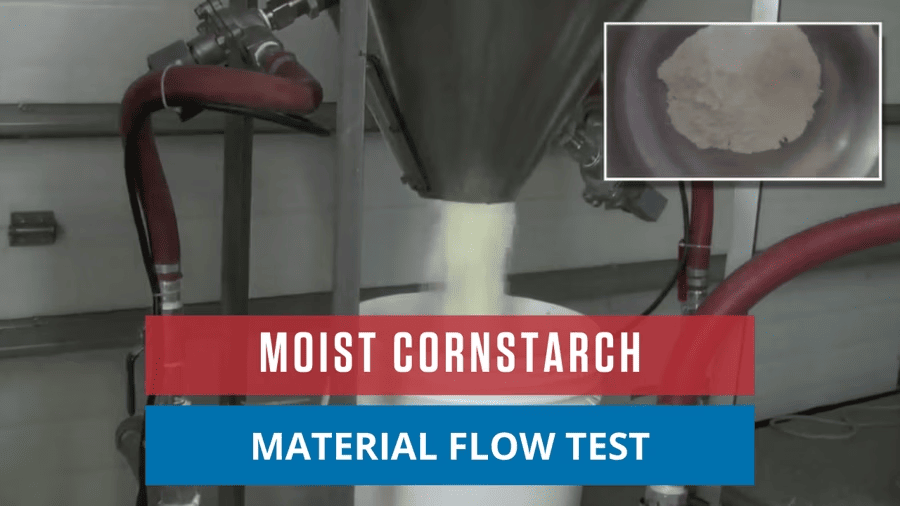

First, 1.3 cubic feet of material was poured into the hopper with a 28” diameter, a 60-degree cone, and a 4” diameter outlet. After the discharge was opened, the material did not flow even when tapped with a rubber mallet. This indicates that Brewer’s grain will not flow readily, if at all, without aid.

Then, four Airsweep VA-06 units were installed on the vessel. Two were placed 180 degrees apart at approximately 4” and 10” above the outlet. The other two were installed 180 degrees apart at approximately 8” above the outlet.

The units were set up to release air pulses starting from the lowest unit, with a pulse duration of 0.25 each and a rate of one pulse every 2 seconds. Material flow increased immediately with the first pulse, and continued to flow until the hopper was emptied entirely.

AirSweep is the most effective pneumatic flow aid for dense, sticky, and compact materials. For this reason, it is used extensively in the pet food industry, including one of the largest pet food manufacturers in North America.