Standard AirSweep vs. Straight Shooter Models

The AirSweep system can handle almost any type of material and can be fitted into several kinds of storage vessels: silos, hoppers, ribbon blenders and more. The nozzles are positioned to release high-pressure, high volume 360° bursts of air. However, your process may require the air to be focused in one direction. Or, there may be structural limitations like a shared wall in the grain bin that make it difficult to install the standard AirSweep.

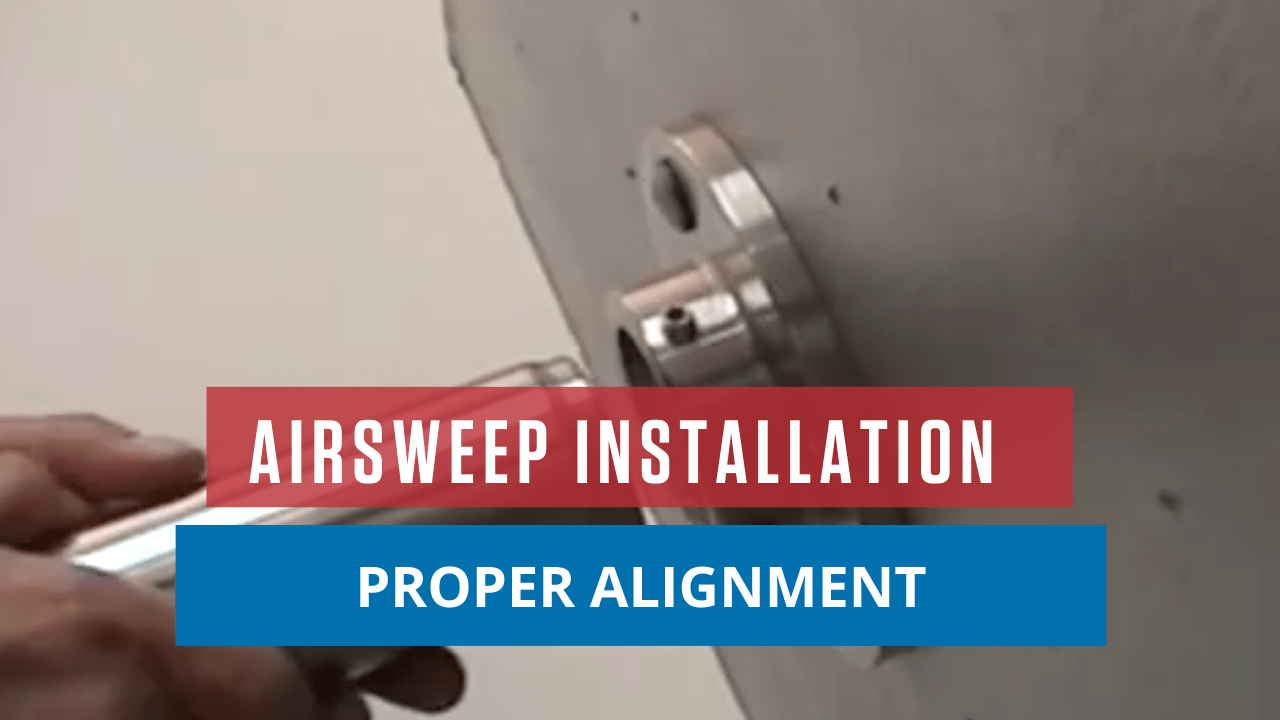

That’s when you need the AirSweep straight shooter models. In this video, Paul the AirSweep guy explains:

- The difference between the standard AirSweep® and the Straight Shooter models

- Situations or applications where the Straight Shooter may work better

- How to adjust the position/location and angle of the Straight Shooter to achieve the desired material flow

The video concludes with a material flow test that shows how the AirSweep Straight Shooter can eliminate ratholing, bridging and other material blocks.

What will work better for your vessel, material, process or industry? The AirSweep engineers can customize the system for you, and recommend the right models and set-up.