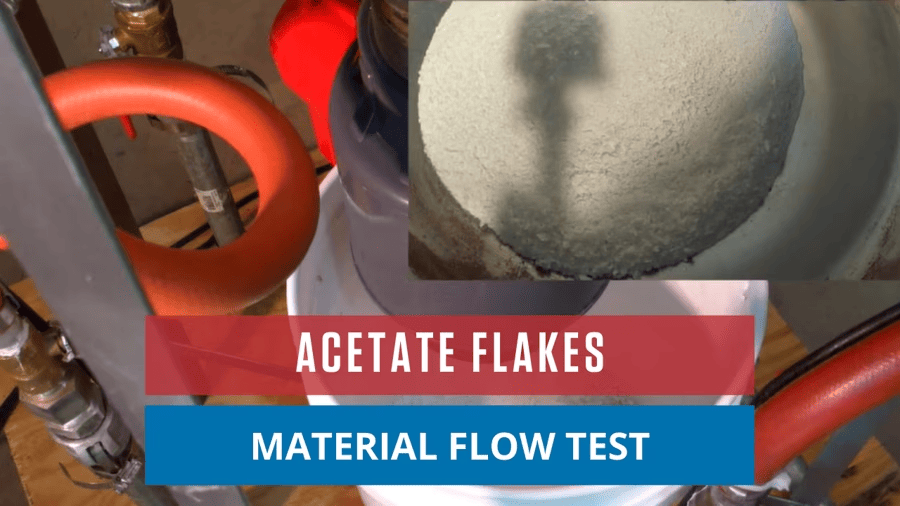

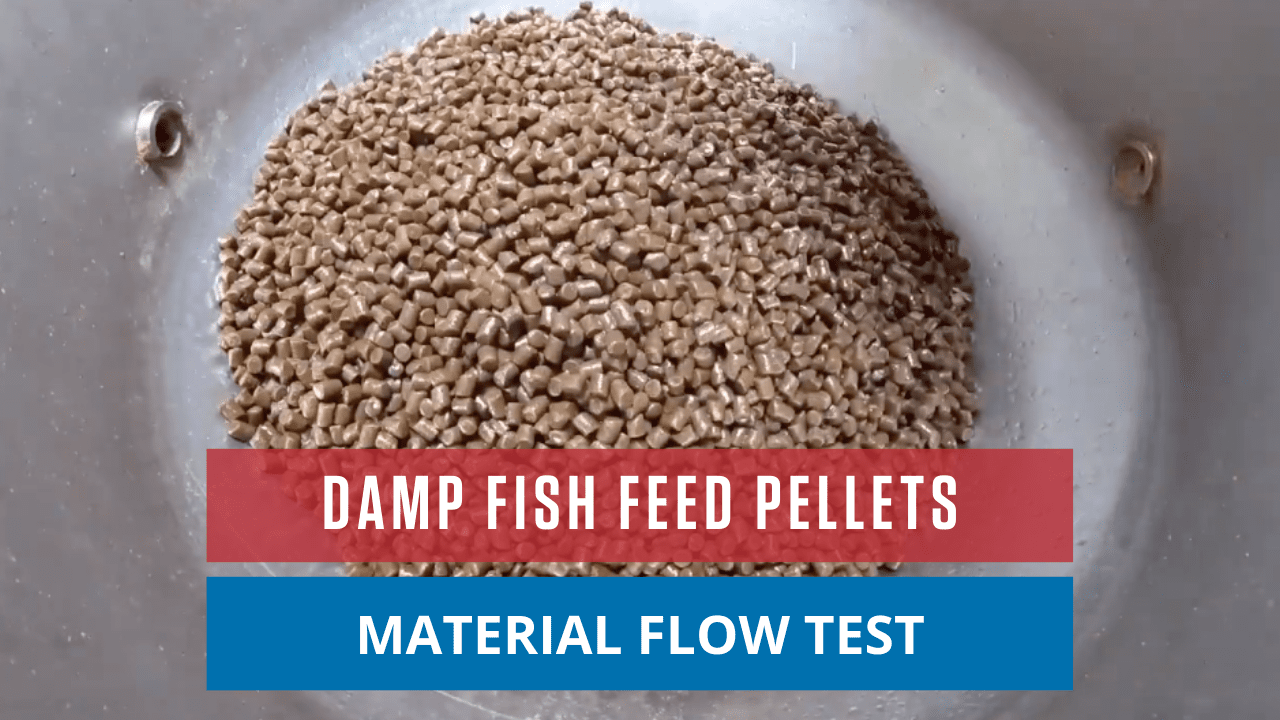

Damp Fish Feed Pellets Material Flow Test

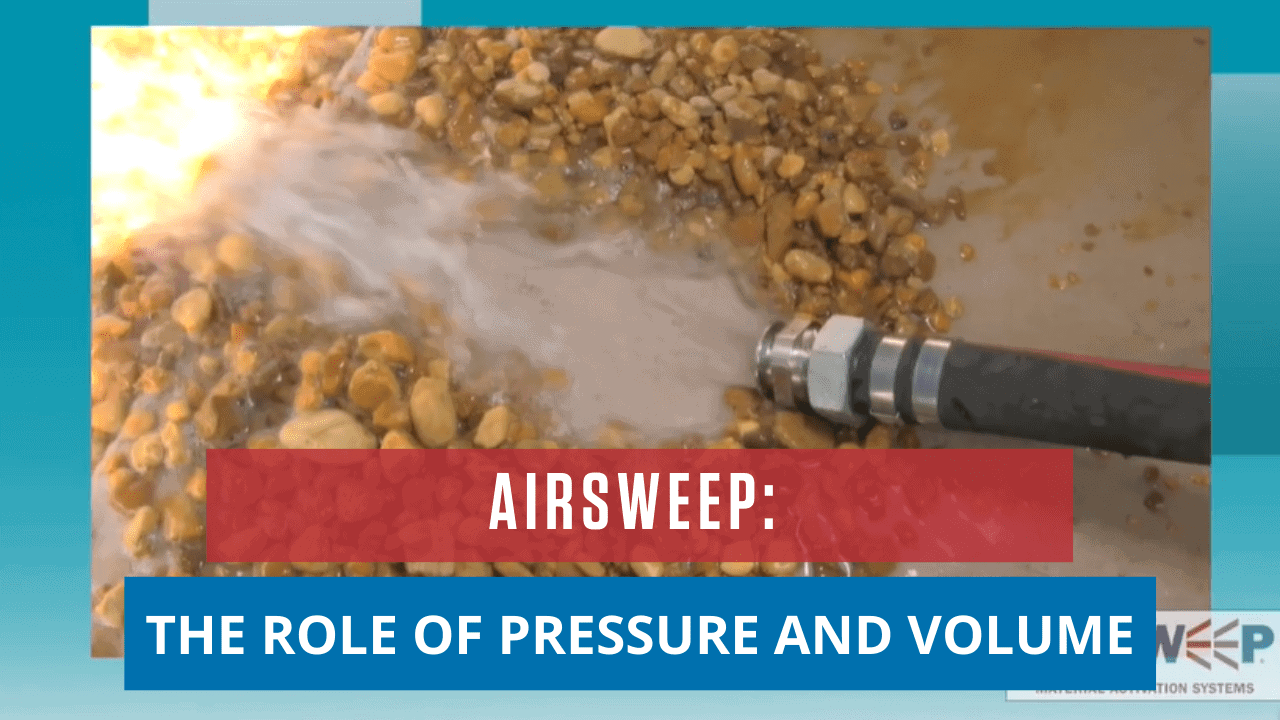

Material flow issues like arching, bridging and ratholing can be caused by a number of factors: moisture and humidity, the size of the particles, the size of the outlet, pressure and chemistry. In this material flow test, we create the conditions that can cause bulk materials like fish pellets to get stuck in a vessel. Can the AirSweep make it flow?

The Setup

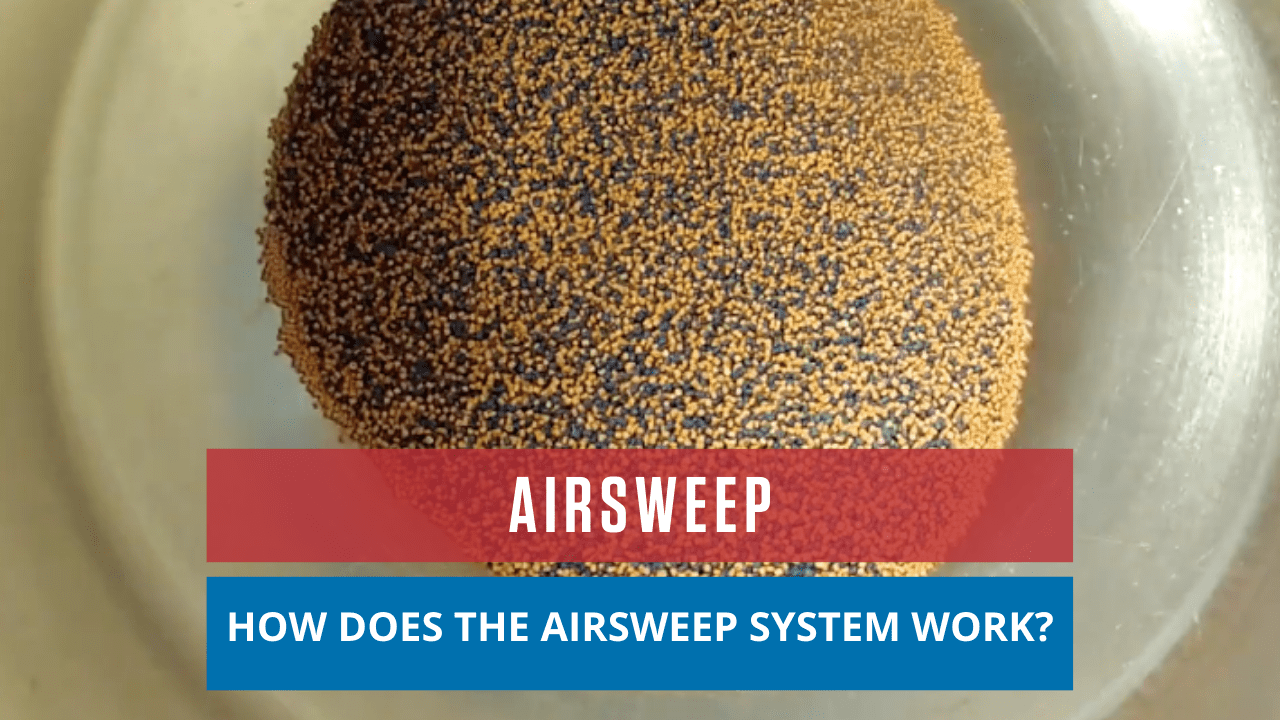

We used fish pellets that are 10 to 13 millimeters long and 7 millimeters in diameter. These were poured into a bin with a 4” diameter discharge. Humidity levels in the plant were 52%.

The AirSweep System

Four AirSweep VA-06 units, placed 90 degrees apart

Challenge # 1

Two gallons of water were added to the pellets. The AirSweep system cleared the bin in seconds.

Challenge # 2

Two additional gallons of water were poured on the moist pellets. The material was then pounded with a wooden block to simulate common issues like packing and caking. Then, the vessel outlet was narrowed to 4 inches – increasing the difficulty of achieving continuous material flow.

Despite these challenges, the AirSweep swept the vessel completely clean with just a few powerful pulses.

Watch the material flow test to see proof of AirSweep’s power and efficiency.