How Air Pressure and Volume Affects Your AirSweep’s Performance

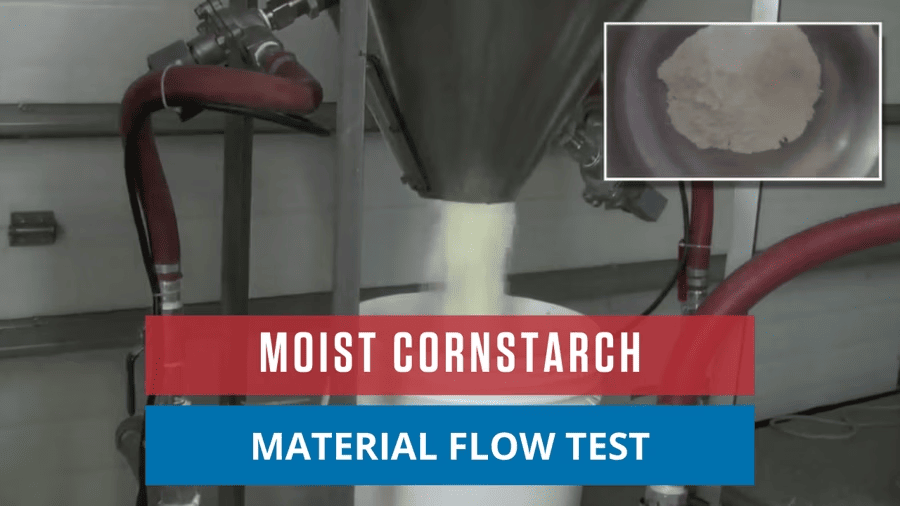

Your AirSweep system clears material blocks with powerful bursts of compressed air. For best results, it’s important to maintain proper pressure and volume.

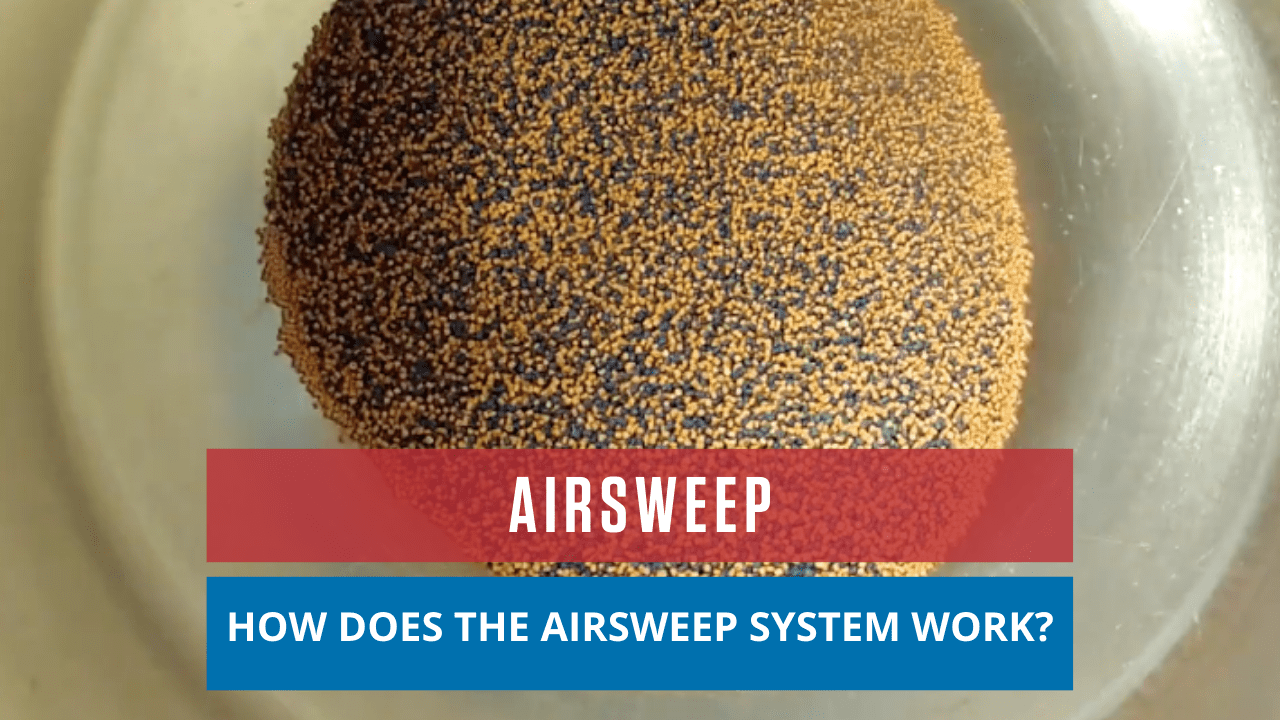

How does an AirSweep system work?

Each AirSweep nozzle directs a high-pressure, high-volume 360° burst of compressed air or inert gas along the inside walls of process equipment or vessels, breaking friction to lift and sweep stalled material back into the flow stream.

The air receiver, air supply line and solenoid valves deliver the compressed air to the nozzle. The Control Concepts engineers will recommend the right set-up and necessary accessories to reach the recommended PSI.

What happens when you don’t supply enough pressure?

This video demonstrates the difference in the AirSweep performance when you change the pressure. If you are experiencing any problems with your AirSweep, check the pressure and volume. If problems persist, do reach out to us—we’ll be happy to help!