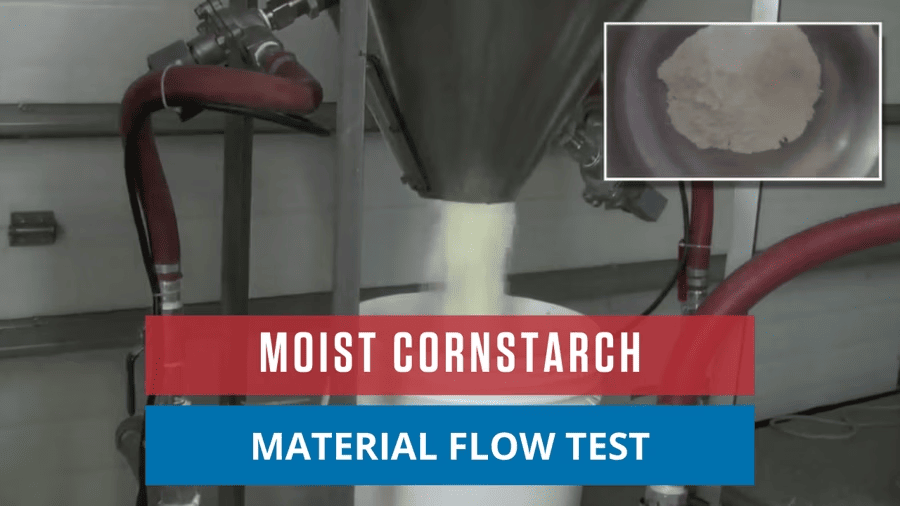

De-germed, De-branned Corn Material Flow Test

AirSweep is the best pneumatic flow aid for tough material flow problems. It can handle challenging powders like titanium dioxide and bulk solids like sticky liquid cheese. In this video, we’ll show you how it deals with dry, caked compounds too.

Half a gallon of water was added to corn grits (DDC) and sprayed along the vessel walls. The mixture was left in the hopper, which was sealed for three days. The plant environment had an average temperature of 73°F and humidity levels of 61%.

After three days, the mixture had caked into a hard and moldy block.

Four AirSweep VA-06 units were mounted on the hopper, at 90 degrees apart. The operating pressure was set to 60 PSI. The air pulses broke the hardened corn grit mixture into fine powders, and cleared the vessel.