Polypropylene Homopolymer Material Flow Test

Polypropylene Homopolymer (PPH) is a thermoplastic resin with a wide range of applications.

PPH is durable and resistant to chemicals and retains its shape even after a lot of bending and flexing. It is often used to make packaging and commodity plastics, textiles, or construction materials such as pipes, sheets, and moldings.

Since PPH has a high electrical resistance, it is also used to manufacture electronics, household appliances, and automobile components.

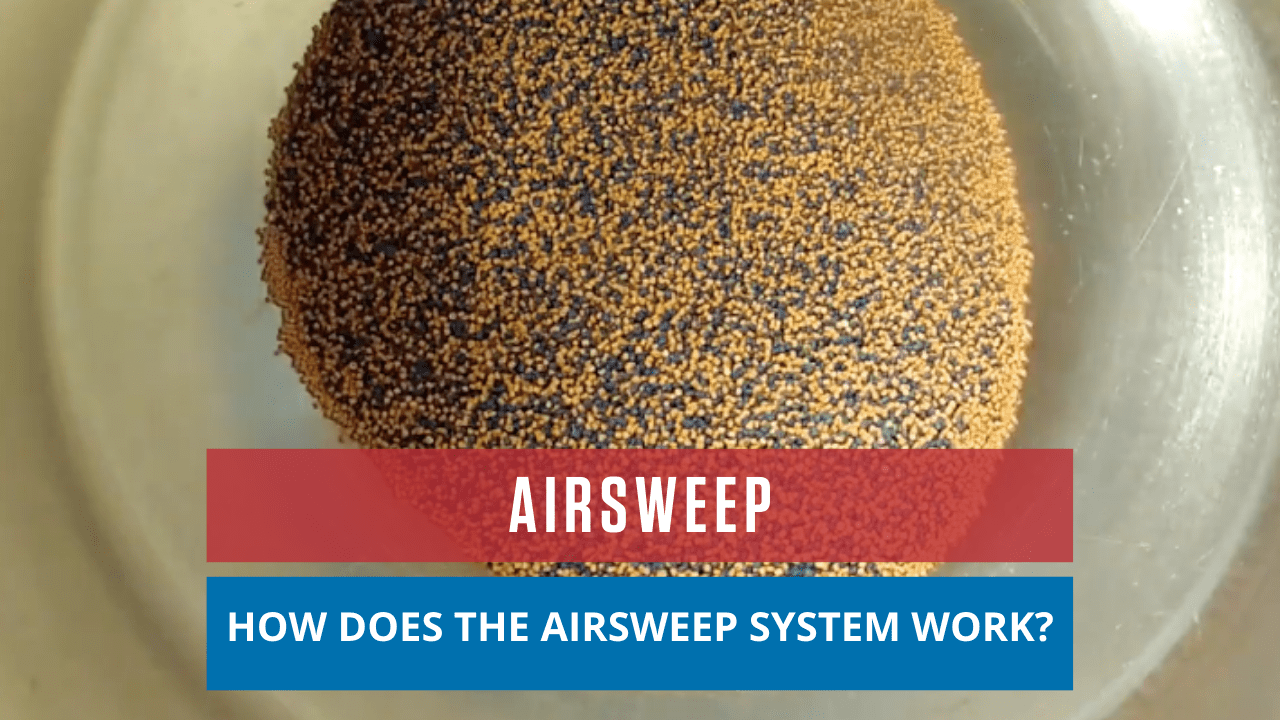

However, shredded polypropylene shavings will not flow readily. It is lightweight, airy, and becomes spongey when compressed. Even with minimal handling, it produces small amounts of dust.

Polypropylene responds to aeration, so pneumatic flow aids like AirSweep can prevent it from bridging, arching, and interlocking in hoppers and other vessels.

In this material flow test, about 10 pounds of polypropylene shavings were placed in a 28” diameter hopper with a 60-degree cone and a 4” diameter outlet. Two AirSweep VA-06 units were installed 180 degrees apart at approx. 8” and 10” above the outlet.

The AirSweep system was set at the operating pressure of 40 PSI, with a sequence rate of one pulse every 3 seconds, each pulse lasting for 0.25 seconds. The material started flowing immediately with the first pulse and continued to steadily flow until the hopper was completely emptied.

AirSweep is an effective flow aid for polypropylene homopolymers and other thermoplastic resins used to make packaging, construction materials, and components.