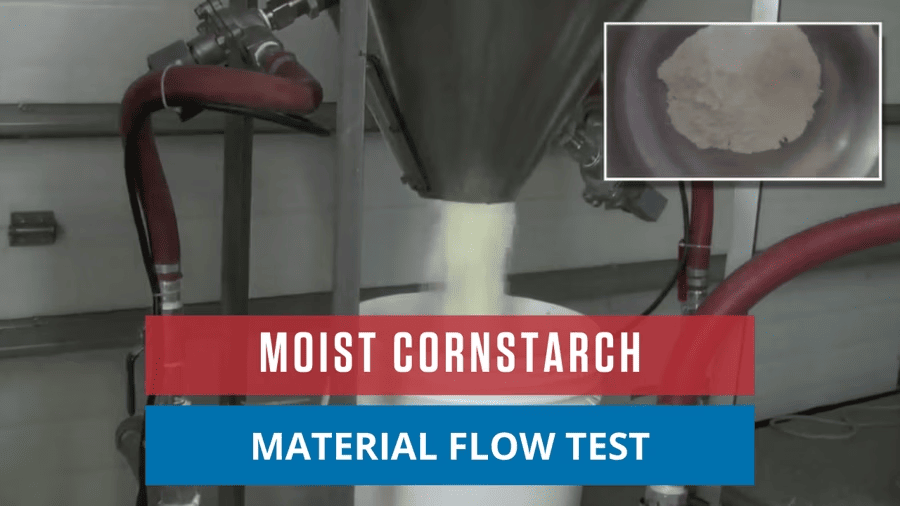

Resin Flakes Material Flow Test

Light, dry material like resin flakes can become compressed during the manufacturing process. It clogs up the discharge, and brings production to a halt. Workers have to hammer the vessel to get it flowing, but—as the video shows—hitting the bin is slow, tedious and inefficient.

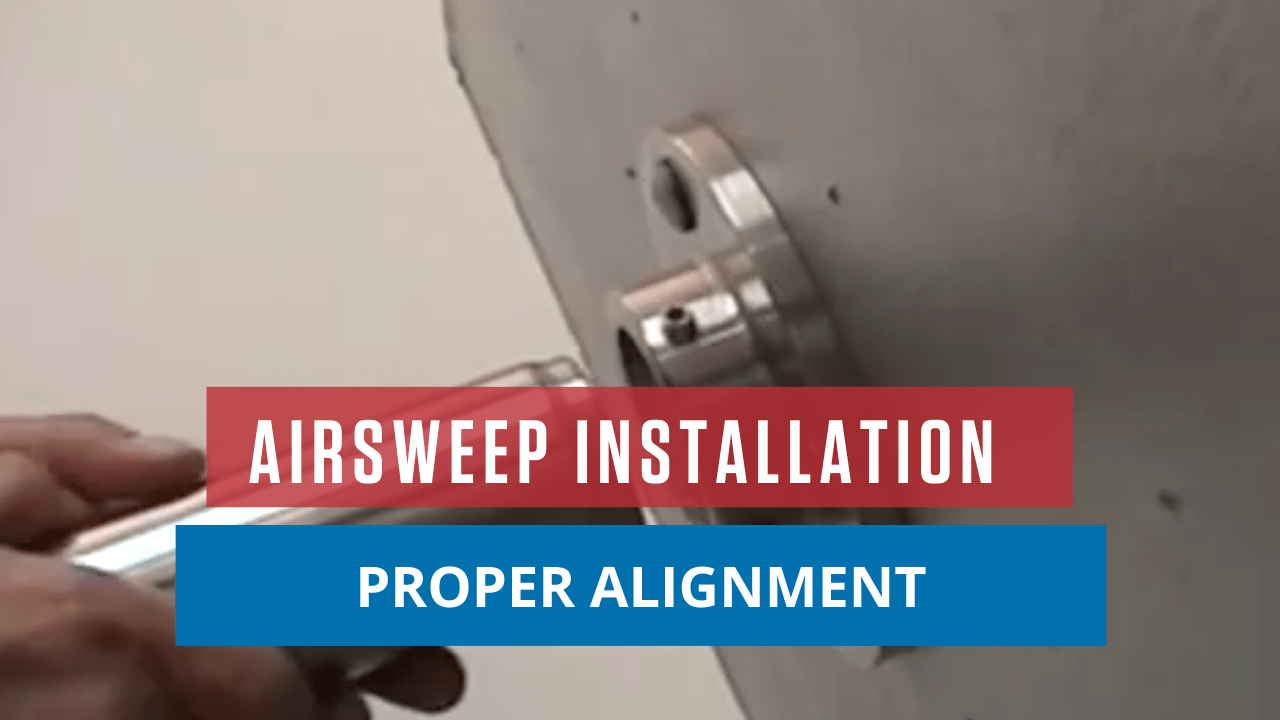

The AirSweep system uses high-pressure, high-volume air pulses to break the friction and push material back into the flow stream. It saves time, prevents downtime and damage to vessels, and improves productivity. It’s the fastest most cost-efficient way to resolve bin bridging, arching, ratholing and other flow problems.

Watch to see proof of how the AirSweep system works on resin flakes and similar materials.