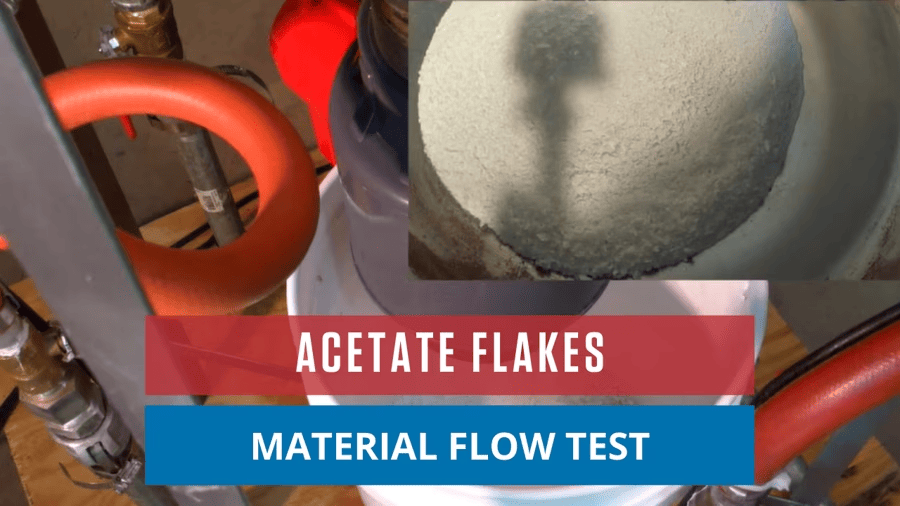

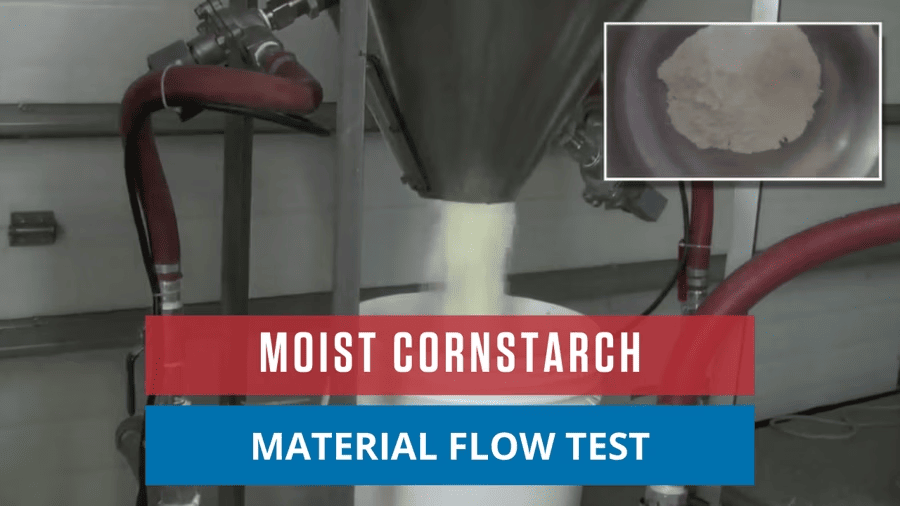

Recycled Material Flow Test

During the manufacturing process, scrap material that has either been rejected or trimmed off can be collected and sent back to the grinder. Reusing recycled material is good for the environment and the bottom line – but it does pose a material flow challenge.

Any recycled material has a heat history that affects its physical, chemical and flow properties. Bridging, arching, ratholing are common. However, many flow aids are unable to activate this bulk material. Fluidizers do not have the pressure or volume. Vibrators can cause it to settle and compact. Air cannons are too expensive to operate round-the-clock, and the recoil can cause long-term damage to the vessel.

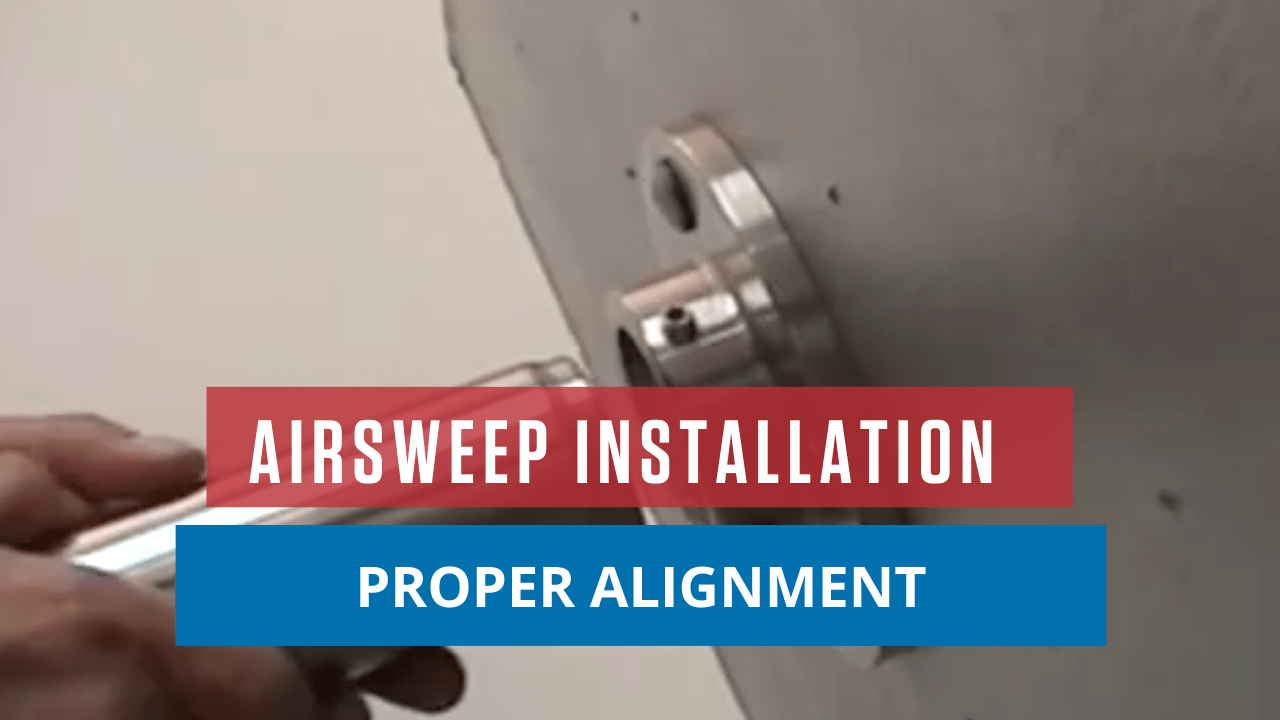

AirSweep can help provide smooth, first-in/first out on-demand flow of all bulk solids, including recycled material. Watch proof of the flow in this video.