AirSweep Protects Product Quality with First-in, First-out Flow

Comments Off on AirSweep Protects Product Quality with First-in, First-out FlowOrganic feeds mill increases productivity, product safety and efficiency

A producer of feed products for organic livestock is known for its high-quality, GMO-free grain. This company runs a certified-organic facility and uses computerized batching and mixing to protect its product integrity. However, a recurring problem affected its quality control: stagnant soybean meal.

Problem

Due to soybean meal’s high fat and protein content, it tends to have sluggish flow properties and stick to vessel walls. It is also more susceptible to becoming rancid.

The company’s soybean meal clumped, caked, and caused bridging and ratholing in their hoppers and cyclones. This slowed down production and increased the risk of product spoilage. A spoiled batch could lead to product recalls and damage their relationships with suppliers.

Solution

Most flow aids don’t work on soybean meal. Fluidizers can’t activate moist or sticky material. Vibrators leave residue on vessel walls and can cause metal fatigue – and any cracks along the maintenance welds increase the risk of product contamination.

Because AirSweep has a proven track record in the food industry for providing first-in, first-out flow for even the toughest materials, it was the ideal solution for this feed producer.

The company installed four AirSweep VA-51 units on their vessels, which included soybean hoppers and cyclone applications.

Results

AirSweep’s powerful air pulses resolved all bridging and ratholing, ensuring first-in, first-out flow of the soybean meal.

Since deploying AirSweep, the feed producer has been able to maintain on-demand flow with few operator interactions, increasing both productivity and efficiency while ensuring consistent product quality.

AirSweep Reduces Battery Component Manufacturer’s Downtime to Nearly Zero

Comments Off on AirSweep Reduces Battery Component Manufacturer’s Downtime to Nearly ZeroThey have worked flawlessly to prevent bridging and improve material flow.

A global battery component manufacturer produces anode and cathode components from recycled batteries. One of its key materials – lithium carbonate powder – was notoriously difficult to handle.

Lithium carbonate powder is fine-grained and has a low moisture content. While it doesn’t clump, it has a high angle of repose that tends to create bridging and ratholing scenarios.

Problem

The lithium carbonate powder tends to bridge and accumulate in hoppers, cyclones and at various parts of the powder handling system. Operators have resorted to hammering of the vessels, but this creates occupational hazards, as lithium carbonate is classified as a skin irritant and is known to cause respiratory problems if inhaled or touched.

Solution

The manufacturer knew from common industry knowledge that fluidizers and vibrators wouldn’t work with the material. AirSweep, which is widely used by lithium carbonate producers, stood out as an obvious solution to save time and capital expenditure.

The AirSweep team responded swiftly. They provided a customized solution within three working days and finalized the system the same week. The items arrived at the plant just two weeks after the company first reached out.

The manufacturer installed AirSweep VA-06 and AirSweep VA-51 units on their pneumatic conveying systems – hoppers, cyclones and at the bottom of their dust collectors. They immediately saw the difference.

Results

“We are quite pleased with our AirSweeps! They have worked flawlessly to prevent bridging and promote material flow,” said the company representative. “We have had zero failures, and they just work great! They reduced our production downtime due to material clogs to nearly zero.”

Coffee Brands Choose AirSweep Over Fluidizers

Comments Off on Coffee Brands Choose AirSweep Over FluidizersLeading global food manufacturer gets free-flowing coffee and improves plant safety too

Food and beverage manufacturer JM Smucker has two coffee brands: Cafe Bustelo and Folgers. Coffee is a hygroscopic material that attracts moisture and has a tendency to clump.

Problem

Large clumps of coffee would build up in the baghouses in the filtration system. Technicians had to climb into the baghouses to break up the clumps, which was a safety concern.

They were considering different flow aids when a colleague from a Folgers plant sent them a video about AirSweep versus fluidizers.

The video compared how much material a single AirSweep unit could activate. They realized that AirSweep had more power than several fluidizers combined. The AirSweep would also pulse every 30 minutes, while the fluidizers would pulse every few minutes – which eventually translated to more energy efficiency and savings.

Solution

They installed a customized AirSweep system with four units strategically located to prevent or break up any clumps of material. Installation was easy too: both technical and sales support helped them with any questions and concerns, so they had no delays with implementation.

Result

AirSweep solved all flow concerns quickly and conveniently. They can control the system’s frequency and they never have to send someone to manually clear the blocks. They have recommended the system to other plants with baghouses. “AirSweep is the way to go.”

AirSweep Gives Instant Flow, 25% Time Savings

Comments Off on AirSweep Gives Instant Flow, 25% Time SavingsAirSweep was the only flow aid that met their specifications, solved the problem and saved energy, too

W. L. Gore & Associates, a global material science company that specializes in films and membranes, was testing a new material for a special fabric used by the military and firefighters for chemical protection. However, material blocks were stalling production and product development.

Problem

They were working with polytetrafluoroethylene (PTFE), a high-performance plastic that can withstand high temperatures and repel water.

However, the material would bridge and pack in the vacuum receivers. Workers had to manually clear the material blocks with rods or hit the vessel with mallets. This would happen five or six times for each run, taking 15 to 20 minutes.

That would add up to an hour of downtime for every four- to five-hour run. “It’s pretty significant when you’re trying to move material at any reasonable rate,” said Zachary Corcoran, the Equipment Process Engineer. “We needed an automated system that didn’t require constant checking because we have other aspects of the process to monitor and we don’t have time.”

However, choosing the right flow aid was also challenging. Some blocked areas were inaccessible. The vessels they used were small and had thin walls, so vibrators or agitators that caused metal fatigue were out of the question. Some pneumatic flow aids like air pads would compromise their vacuum system.

Solution

Zachary read about AirSweep in Powder & Bulk Solids. “I had a direct call with the sales team, and expressed my concerns on vessel size and running a flow aid in a system that is usually under a vacuum when pulling the material.”

The AirSweep engineers recommended the AirSweep VA-06. It was just the right size for their material and vessel and could reach inaccessible areas.

And unlike other pneumatic flow aids, the AirSweep nozzle also released very short, controlled air pulses. It was safe to use in a vacuum system, and more energy efficient.

Installation was simple and seamless. “It was quick to get here, and all the resources were provided to us like the installation guide and even the air tank. That was pretty helpful since we didn’t have to search for outside vendors to get all the necessary

pieces.”

Installation, including welding and connecting it to the air system, only took four hours.

Results

Immediately after the first trial run, W. L. Gore & Associates ordered two more AirSweep systems for their other plants.

“AirSweep saved us one hour of downtime for every four-hour run – or 25% time savings,” said Zachary. “Instead of babying the process, we can focus on production and doing our jobs”

AirSweep is also helping them save on costs. “Air efficiency is also a big piece of it for us. Our vessels are so small, so we have pretty significant savings on compressed air by just having short pulses rather than an air pad that is constantly running.”

As for recommending AirSweep to other manufacturers, Zachary has this to say: “We’re going to be ordering another full system for another plant overseas, so I think that speaks for itself.”

AirSweep Exceeds Expectations – “You Should Be On Billboards Everywhere”

Comments Off on AirSweep Exceeds Expectations – “You Should Be On Billboards Everywhere”A mining company struck gold with AirSweep’s performance, safety, and service

First Quantum Minerals Ltd., one of the fastest-growing mining companies in Africa, needed a reliable way to move copper concentrate through the chutes. However, other flow aids damaged the vessels or created safety hazards.

Problem

The material – a solid mixture with a fine particle size of 18% to 24% copper, sulfur, and silica – clogged the chutes while being transferred from storage bins to the furnace.

Vibrators didn’t work and damaged the vessel walls. Workers still spent up to two hours each day clearing the chutes by hosing them with compressed air or hammering the walls. When copper supplies ran low, they also had to close down the furnace to wait for the chutes to be re-activated.

“This was not a sustainable practice. We were losing time and compressed air that could be used elsewhere,” said Emmanuel Mudenda, a Metallurgist for Kansanshi Copper Smelter.

Solution

The material they used was very dense and heavy, and could not be activated with fluidizers or other light flow aids. However, air cannons were too loud and dispersed material in explosive bursts. This was a safety issue – and First Quantum was known for being one of the safest in Africa.

They emailed AirSweep and were pleasantly surprised to get a response immediately. They were able to install the system without any problems and got instant results.

Results

With AirSweep in place, the mining company had no issues with material blocks in the chutes. Workers can focus on other aspects of production, and they don’t have to worry about vessel damage or noise from vibrators or hammers. “AirSweep is quiet and effective,” said Emmanuel.

“The performance has been so good that we would like to install the same device on a few other chutes. Customer service is also top-notch,” he added. “ You guys should be on billboards everywhere.”

AirSweep: Prescription for Poor Material Flow

Comments Off on AirSweep: Prescription for Poor Material FlowA PHARMACEUTICAL COMPANY SOLVES THEIR BIGGEST HEADACHE WITH AIRSWEEP

Material flow can be a headache—especially for pharmaceuticals. To manufacture tablets, powder ingredients are mixed in a blender and then discharged into a bin or a hopper, from where they are fed to the tablet press. Unfortunately, many fine powders are prone to bridging, arching, and segregation. This was the problem that plagued a global, multi-billion pharmaceutical company, and AirSweep proved to be the perfect prescription.

Problem

During the production of acetaminophen, an over-the-counter drug, multiple powder ingredients would bridge in the hoppers. This not only slowed down production, but if the arch or bridge suddenly breaks, the overflooding can affect downstream processes, and be hard to clean up.

Erratic flow also compromises product consistency and quality. This can lead to the rejection of batches worth hundreds of thousands of dollars and poses a risk to the pharmaceutical’s reputation and the safety of its products.

Solution

The company asked the AirSweep team to do a material flow test and found that the powders responded very well to the AirSweep system. Installation took less than 48 hours.

Result

With the AirSweep in place, the pharmaceutical company was able to achieve on-demand, reliable material flow in their acetaminophen production.

“With acetaminophen being for human consumption, we cannot have non-uniform batches due to inconsistent material flow. It was costing us thousands to discard those batches. After installing AirSweep, it was a success and we immediately added AirSweep to another one of our process lines” – Project Director, Corporate Engineering.

Dazic Prevents a Dangerous Dust

Comments Off on Dazic Prevents a Dangerous DustGlobal tire manufacturer installs DAZIC to meet plant safety standards

Carbon black is used in the production of rubber tires to improve durability and performance. However, OSHA classifies it as a combustible dust, and requires companies to prevent it from accumulating.

One of the world’s largest tire manufacturers uses DAZIC® zero speed switches to meet plant safety standards.

Problem

If equipment malfunctions and causes a carbon black spill, it creates a dangerous plant environment. Finely dispersed particles can form explosive mixtures in the air and cause flash fires. It also causes coughing, breathing problems, and skin or eye irritations.

Since carbon black doesn’t dissolve in water and solvents, clean-up is long and difficult. This prolongs worker exposure, and stalls production for days.

Solution

The tire manufacturer installed DAZIC zero speed switches to signal the operator if equipment stops or runs too fast—preventing material flooding and spills.

Results

With DAZIC in place, there have been no incidents of material pile-up. It was a reliable and affordable solution—and thanks to the DAZIC customer service, was very simple to implement. “They have been very responsive to the process needs of our factory.”

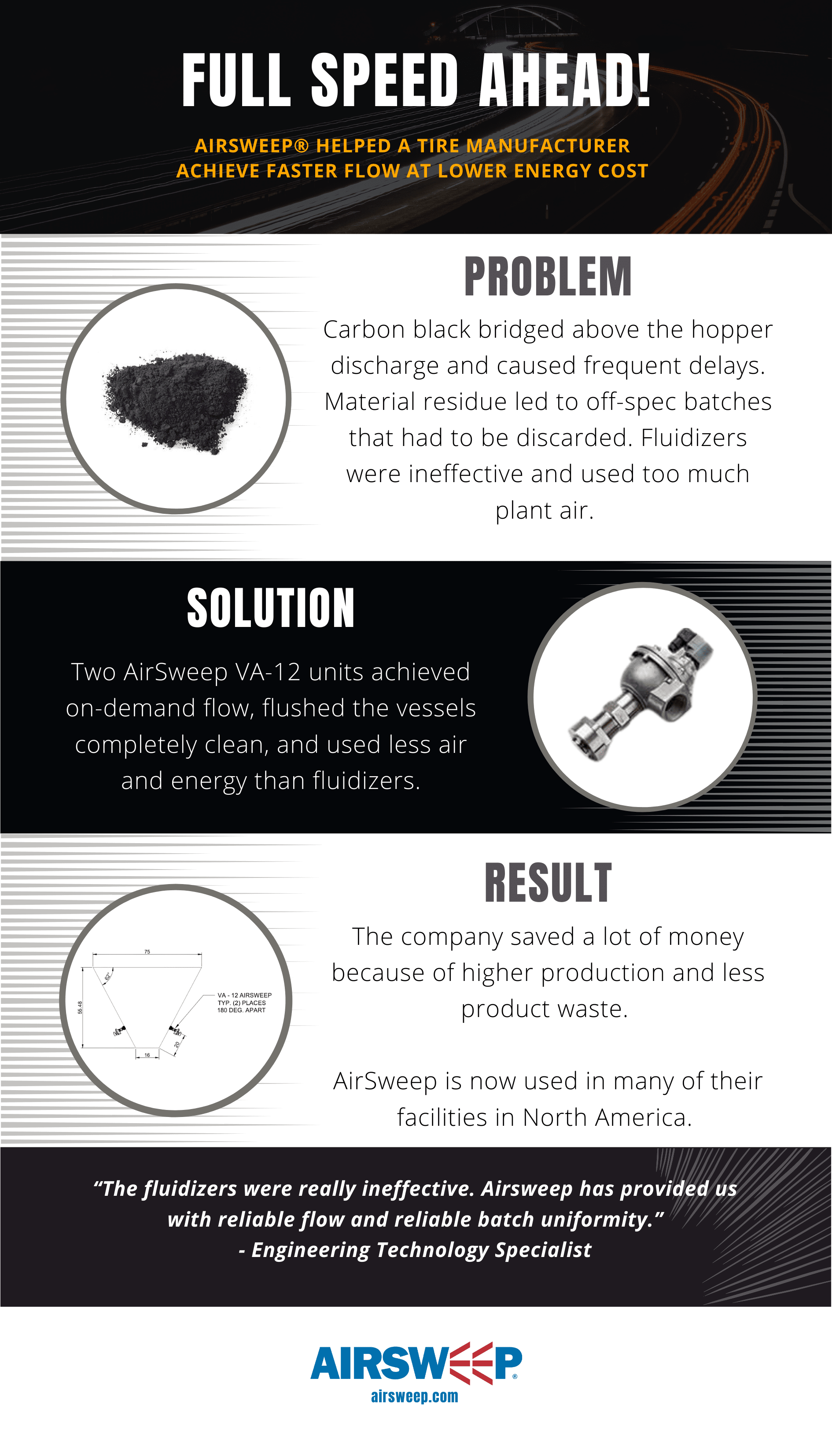

AirSweep: Full Speed Ahead

Comments Off on AirSweep: Full Speed AheadAirSweep® helped a tire manufacturer achieve faster flow at lower energy cost

One of the world’s largest tire manufacturers had hit a roadblock in production, because of the poor flow characteristics of one of its most important materials.

Carbon black is used in the production of rubber tires to improve durability and performance. It conducts heat away from the tread and belt area, and can reduce rolling resistance.

However, carbon black is a very challenging material to handle. It cakes and packs easily, and leaves deposits on every surface it touches.

Problem

The manufacturer faced two problems that were costing them time and money.

First, carbon black bridged above the discharge. This stalled the weighed batch of material and caused frequent process delays.

Second, it coated the interior of the vessel and compromised batch uniformity. Several batches that proved off-spec during quality testing had to be thrown out.

The manufacturer initially tried fluidizers, but these were ineffective and expensive to operate. They wanted a flow aid that created on-demand flow, but used plant air and energy more efficiently.

Solution

AirSweep proved to be the most reliable, cost-effective solution for a problematic material like carbon black.

Two AirSweep VA-12 units were installed on the weigh hopper. This size is ideal for medium to large vessels when it’s important to limit the volume of air introduced into the system—either to avoid over-aeration of the product, or when plant air is limited or costly.

The AirSweep system could be set up to release pulses in a specific time and sequence. It used less compressed gas than fluidizers, which would run continuously. The pulses could also be positioned at problem spots to prevent bridging and flush away residue.

Results

The AirSweep system ensured smooth, continuous flow of the carbon black material. The plant achieved higher production and batch uniformity, and saved a lot of money because of lower energy consumption and product waste.

Because of AirSweep’s proven success, the tire manufacturer has installed additional units in other parts of the plant. The system is now being used in several of their facilities in the United States and Canada.

“The fluidizers were really ineffective,” said the manufacturer’s engineering technology specialist. “Airsweep has provided us with reliable flow and reliable batch uniformity.”

The manufacturer has also been very happy with the service of the Control Concepts team. “They have been very responsive to the process needs of our factory.”

AirSweep Proves to be the King of Carbon Black Material

Comments Off on AirSweep Proves to be the King of Carbon Black MaterialVibrators couldn’t handle carbon black, but AirSweep achieves on-demand flow in less than a week

A global manufacturer of carbon black additives supplies over 2 million tons to leading companies in the paint, plastic, tire, rubber, and ink industries every year.

Problem

Carbon black’s flow properties make it particularly difficult to handle. It has a tendency to fluidize, and form deposits along the conveyor lines and storage vessels. Since it does not dissolve in water and solvents, cleaning can be time-consuming and expensive.

Carbon black also has a tendency to cake and pack while unloading, and bridge or rathole in the hoppers. For this manufacturer, bridging over the silo discharge would cause long and frequent process delays. The entire process would shut down because the rest of the machines were starved of raw materials.

Solution

After finding out that vibrators were ineffective, the manufacturer switched to AirSweep—and saw immediate results.

Three AirSweep VA-51 units were installed on a weigh hopper. The air pulses easily activated the material for reliable, on-demand flow.

And it was quick – installation took less than 48 hours.

Results

AirSweep has proven to be so reliable, that the company had the AirSweep system retrofitted to several other process hoppers at the facility.

“I’m extremely happy at the responsiveness of Control Concepts and the local distributor they brought in to work with us,” said the lead process engineer. “Their helpfulness got our project off the ground in less than a week.”

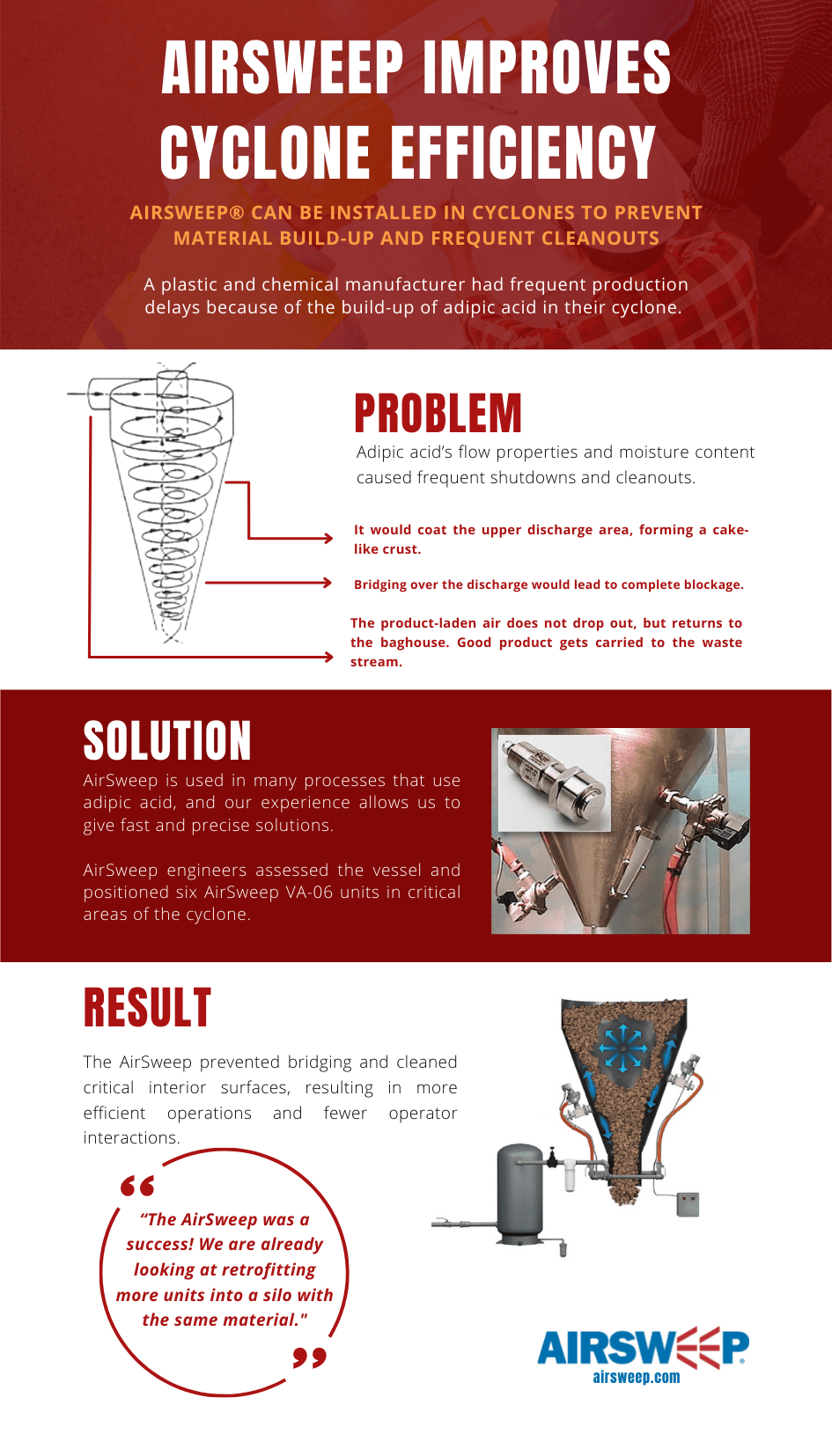

AirSweep Improves Cyclone Efficiency

Comments Off on AirSweep Improves Cyclone EfficiencyAirSweep® can be installed in cyclones to prevent material build-up and frequent cleanouts

A plastic and chemical manufacturer had frequent production delays because of the build-up of adipic acid in their cyclone.

Problem

Adipic acid’s flow properties and moisture content caused frequent shutdowns and cleanouts. It would coat the upper discharge area, forming a cake-like crust. Bridging over the discharge would lead to complete blockage. The product-laden air would also fail to drop out, and return to the baghouse. As a result, good product would get carried to the waste stream.

Solution

AirSweep is used in many processes that use adipic acid, and our experience allows us to give fast and precise solutions.

AirSweep engineers assessed the vessel and positioned six AirSweep VA-06 units in critical areas of the cyclone.

Results

The AirSweep prevented bridging and cleaned critical interior surfaces, resulting in more efficient operations and fewer operator interactions. “The AirSweep was a success! We are already looking at retrofitting more units into a silo with the same material.”