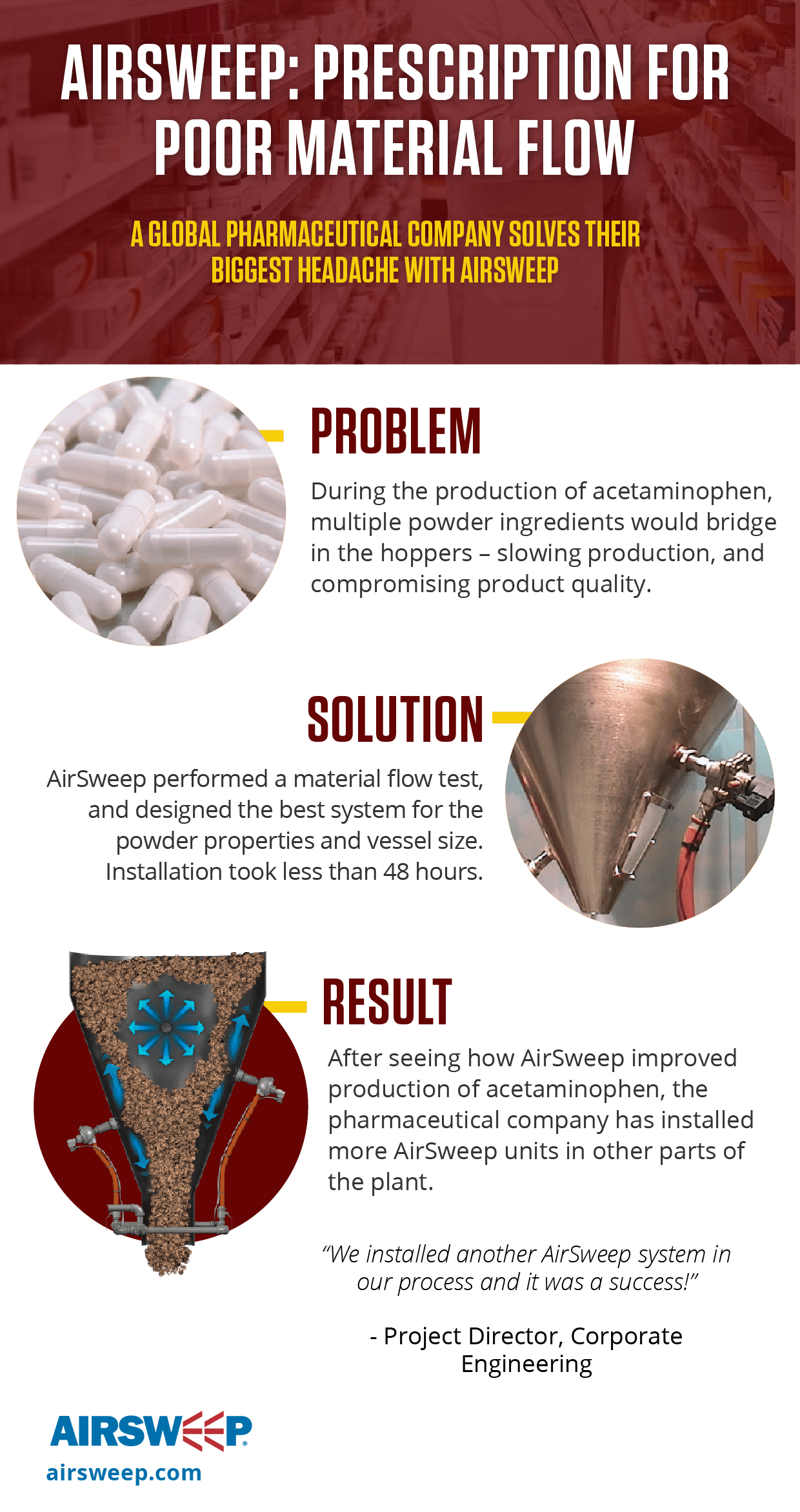

AirSweep: Prescription for Poor Material Flow

A PHARMACEUTICAL COMPANY SOLVES THEIR BIGGEST HEADACHE WITH AIRSWEEP

Material flow can be a headache—especially for pharmaceuticals. To manufacture tablets, powder ingredients are mixed in a blender and then discharged into a bin or a hopper, from where they are fed to the tablet press. Unfortunately, many fine powders are prone to bridging, arching, and segregation. This was the problem that plagued a global, multi-billion pharmaceutical company, and AirSweep proved to be the perfect prescription.

Problem

During the production of acetaminophen, an over-the-counter drug, multiple powder ingredients would bridge in the hoppers. This not only slowed down production, but if the arch or bridge suddenly breaks, the overflooding can affect downstream processes, and be hard to clean up.

Erratic flow also compromises product consistency and quality. This can lead to the rejection of batches worth hundreds of thousands of dollars and poses a risk to the pharmaceutical’s reputation and the safety of its products.

Solution

The company asked the AirSweep team to do a material flow test and found that the powders responded very well to the AirSweep system. Installation took less than 48 hours.

Result

With the AirSweep in place, the pharmaceutical company was able to achieve on-demand, reliable material flow in their acetaminophen production.

“With acetaminophen being for human consumption, we cannot have non-uniform batches due to inconsistent material flow. It was costing us thousands to discard those batches. After installing AirSweep, it was a success and we immediately added AirSweep to another one of our process lines” – Project Director, Corporate Engineering.