AirSweep Reduces Cleaning and Maintenance Time

Comments Off on AirSweep Reduces Cleaning and Maintenance Time

Periodic cleaning and maintenance of vessels can cause significant costs and downtime. However, many companies have found a simple way to streamline this process and further achieve material handling automation. They use AirSweep to improve material flow and flush vessels completely clean.

How does AirSweep help clean the vessels?

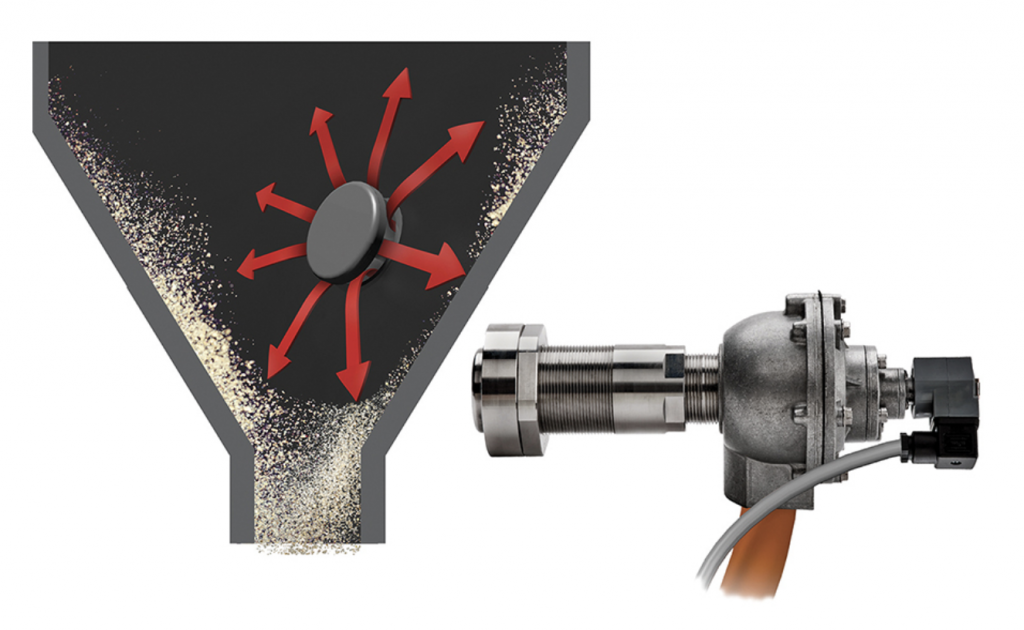

AirSweep releases high-pressure, compressed air pulses that can be released in 360-degree or vertical columns. The nozzles can be strategically placed at specific points in the vessel and timed to release in a particular sequence.

Unlike other flow aids that rely on mechanical force or gravity, AirSweep’s air pulses create a powerful, controlled flow within the vessel. It dislodges even the most stubborn materials and ensures that every nook and cranny of the vessel is thoroughly cleaned – leaving no residue behind.

Why should you use AirSweep to streamline cleaning cycles?

While AirSweep is primarily used to prevent bridging, ratholing, and material blocks, many companies use the technology to flush vessels between batch runs.

Save time and increase productivity

One of the world’s largest manufacturers of infant formula uses AirSweep to clear material build-up in between batch runs of regular and lactose-free milk.

They use the AirSweep USDA 135, engineered specifically for sanitary applications, and the AirSweep Straight Shooter. The combination of air pulses released at 360 degrees and air pulses released in a vertical column allow them to flush different kinds of vessels – blenders, receivers, sifters and even packaging line vessels.

AirSweep has reduced the time and labor needed to clean after the batch runs were completed. This allowed them to add batch runs and increase production output.

Lower cost and material waste

A leading spice and flavor blends manufacturer with facilities in 25 countries around the world used to manually clean their ribbon blenders by flushing them out with flour. This system was expensive and labor-intensive, and still left some spice residue that could compromise batch uniformity.

After installing AirSweep, they achieved a 62% reduction in flour flush and a 42% reduction in labor, all directly attributed to the AirSweep units. They saved $200,000 a year from flush material reduction alone.

Is AirSweep hard to clean and maintain?

The AirSweep unit itself is designed to shorten cleaning and maintenance times. With the AirSweep Tri-Clover Clamp the nozzle can be dismantled and then reattached within minutes with a few basic hand tools. The nozzle can also withstand corrosive cleaning materials.

Does AirSweep meet sanitary requirements?

Many industries that need frequent vessel cleaning or flushing need sanitary equipment. This includes food, biotechnology, pharmaceuticals, and nutraceuticals. The USDA-accepted AirSweep is designed to meet the strictest sanitary requirements.

AirSweep: the complete solution for lowering factory downtime

AirSweep is the only flow aid that can be used to reduce material blocks and flush vessels clean. This combination of features makes it one of the best ways to improve productivity and reduce downtime.

Contact us to find out more about AirSweep and how it can improve your material handling automation and overall plant efficiency.