Cement manufacturing is a complex process that can easily be compromised by poor material flow. From challenging bulk materials to moist fine powders – which all must be mixed at perfect proportions – it’s critical to keep material flowing and the process going.

Cement processing issues

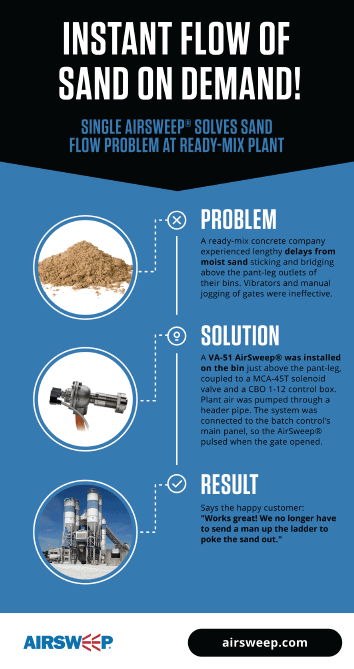

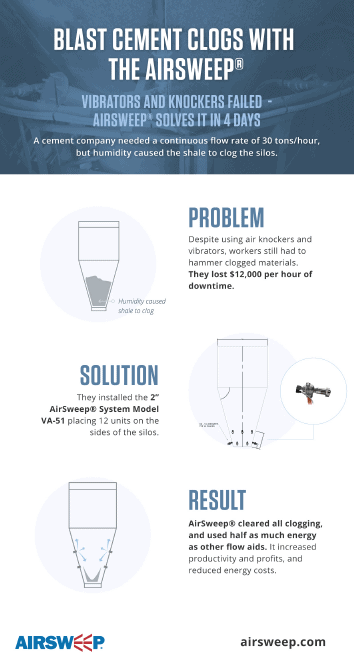

Cement uses some of the most challenging bulk materials, including fine or moist limestone, slag, clay and bauxite. The cohesive and adhesive properties that make them so ideal for construction also create issues like bridging, ratholing, and flooding. This affects product quality and productivity. If you manually clear your vessels with hammers, it can cause work hazards and damage vessels too.

What’s the best flow aid for the cement industry?

Cement factories need a powerful, effective material flow system that can handle all the materials in the process: bulky materials like crushed limestone, sticky materials like clay and moist sand, and very fine powders.

This video compares different flow aids like rubber fluidizers, vibrators and the AirSweep® system.

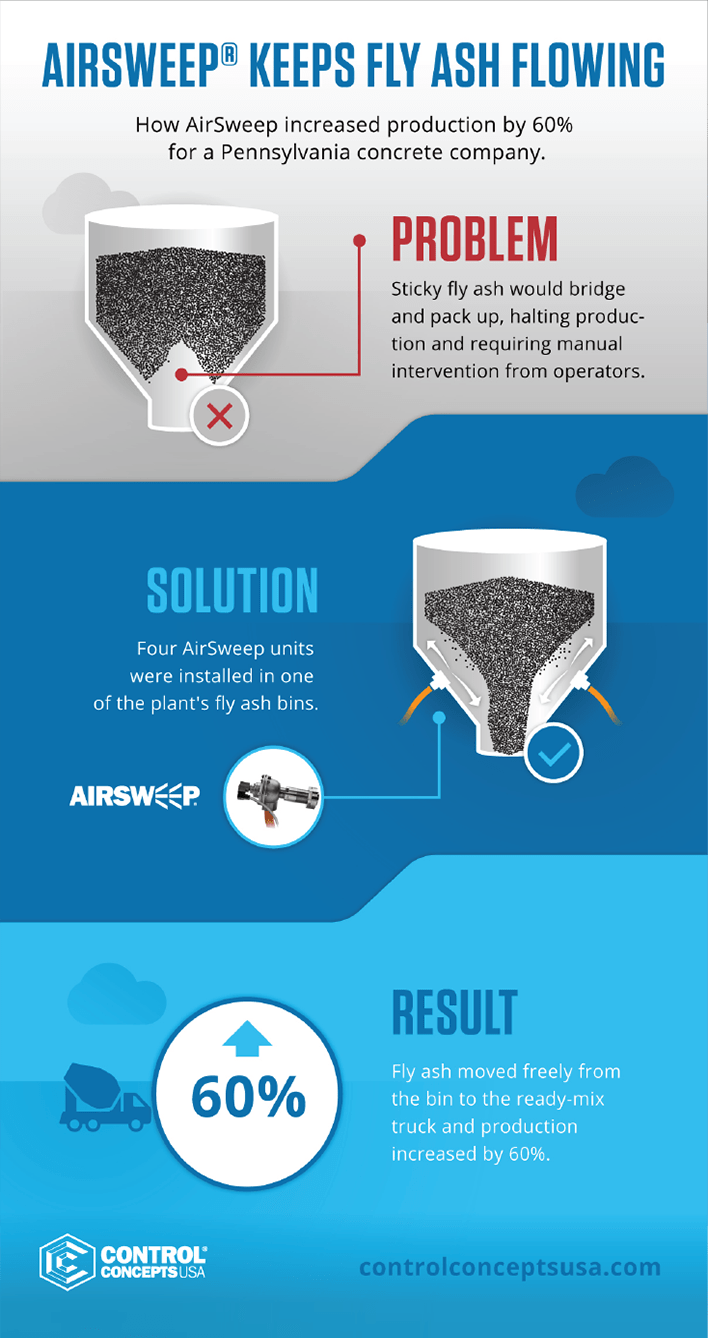

AirSweep®: Proven effective for Cement and Concrete production

AirSweep is used in the factories of some of the biggest cement manufacturers in Asia and North America. AirSweep® nozzles release powerful, high-pressure/high-volume, 360-degree bursts of compressed air or gas between the material and vessel wall to lift and sweep stagnated material back into the flow stream.

It is proven effective for:

- Aluminum

- Bentonite

- Coal

- Copper

- Diatomaceous earth

- Gypsum

- Iron ore

- Limestone

- Magnetite

- Phosphate

- Shale

- Soda Ash

Here are some of the cement and concrete manufacturers who rely on AirSweep to solve material blocks. We have helped them:

SAVE MONEY

SAVE TIME

Clear the kilns with AcoustiClean®

Aside from blocks in storage vessels, cement manufacturers face another common issue: soot build-up in the cement kiln. Even just 1/8″ (3.2mm) of soot can cause 47% heat loss and increase fuel consumption by 8.5%.

Most cleaning solutions can’t take the heat – literally. Soot blowers melt in intense temperatures, and rapping systems can damage tubes. However, our AcoustiClean sonic horns have been used in the construction industry. The cast-iron finish withstands extreme temperatures, and the gentle sound vibrations clear soot without damaging equipment.

Read Full Case Study

Discover how AirSweep and AcoustiClean can improve your cement production and quality

Get a customized quote based on your specifications, and a calculation of your AirSweep ROI. Over time, the money you earn from higher productivity and the money you save from energy and maintenance will make AirSweep the smartest investment you can make.

Get a custom engineered quote