Common Material Flow Problems in Pet Food Production

Contamination and Spoilage

Microorganisms and bacteria can grow in trapped material, or grow on the vessel itself.

Blend uniformity

Sluggish and erratic flow compromises the proportion of materials, affecting the pet food’s quality and nutritional value

Cleaning

Kibble fines must be flushed from the vessel before the next batch. Manual cleaning takes too much time, and using flush material incurs costs.

AirSweep: Proven Solution for Tough Flow Problems

Pet food companies – as well as food and agriculture companies that have similar concerns – use AirSweep to improve material flow.

AirSweep releases high-pressure, high-volume air pulses that sweep all material back into the flow stream.

It can be used during production to prevent material blocks and ensure blend uniformity, and between runs to flush vessels completely clean.

THE BEST FLOW AID FOR PET FOOD MANUFACTURING

AirSweep’s precise air pulses can be used on all raw materials, blends and the finished product

See More VideosPET FOOD COMPANY SWITCHES TO AIRSWEEP

AirSweep proved more effective than other flow aids for pet food production.

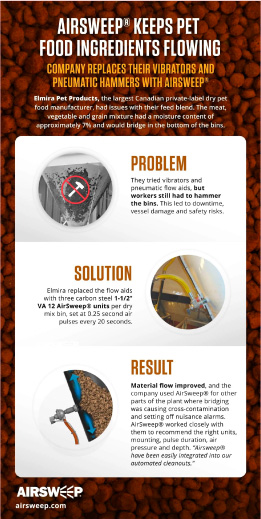

Elmira Pet Products had issues of feed blends bridging in the bottom of the bins. Vibrators and pneumatic hammers didn’t work. Operators still had to hit the bins with sledgehammers, and climb into the two-story vessel to clean the receiver.

AirSweep cleared material blocks quickly and safely. “Initial results have been positive, and the Airsweep® have been easily integrated into our automated cleanouts.”

READ FULL CASE STUDY

AIRSWEEP VS OTHER FLOW AIDS

Pet food uses many problematic bulk solids and powders that can clump and cling to vessel walls.

Vibrators and fluidizers are ineffective, cause vessel damage, and are difficult to clean and maintain.

DESIGNED FOR FOOD SAFETY AND SANITARY PROCESSES

AirSweep’s USDA-accepted models are specially designed to meet the highest standards of sanitation and hygiene.

- Airtight nozzle prevents material retention and bacterial growth

- Modular construction for easy cleaning and inspection

- Tri-flange mount for tool-less removal

COMPLETE SOLUTIONS TO PREVENT DOWNTIME

TAKE CONTROL OF YOUR PROCESS

AirSweep®, AcoustiClean® and DAZIC® can be integrated into different parts of your plant to increase efficiency and minimize cost.