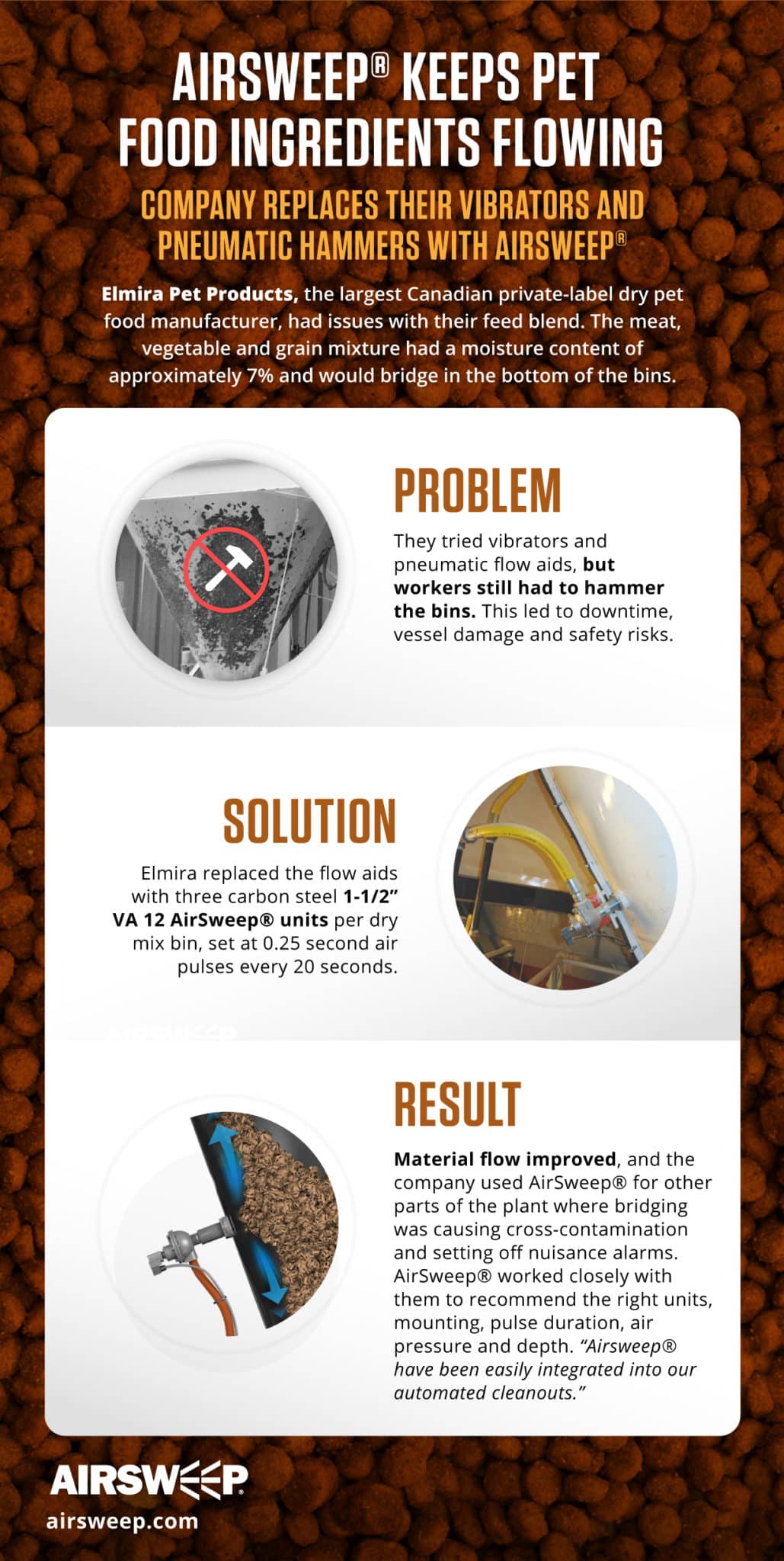

AirSweep® Keeps Pet Food Ingredients Flowing

Company replaces their vibrators and pneumatic hammers with AirSweep

Elmira Pet Products, the largest Canadian private-label dry pet food manufacturer, produces well-known brands for mass merchandise, grocery and the pet specialty channels as well as unique diets for distribution to niche markets.

Problem

In 2014, Elmira Pet Products added two dry mix staging bins to existing bins. The two new bins immediately had issues with product flow due to bridging in the bottom of the bins, particularly above the slide gate. The feed blend consisted of meat and vegetable meal, ground grains and minerals, with a moisture content of approximately 7%.

Vibrators and pneumatic hammers were employed to activate the material flow and eliminate the bridging. Neither solution was effective. Operators resorted to hammering the bins with sledgehammers to dislodge the material. Consequently, downtime increased, bins were being damaged from the hammering, and operators had to climb two stories of stairs and ladders to get the product moving again — creating a safety risk.

Solution

Elmira contacted Control Concepts, Inc. to inquire about replacing vibrators and pneumatic hammers with the AirSweep system.

The AirSweep team designed placement drawings for each bin, paying particular attention to the area above the discharge flange.

The system consisted of three carbon steel 1-1/2” AirSweep VA-12 units per dry-mix bin, strategically placed to stimulate flow in the areas that were backed up with material. A programmable sequence controller triggered 0.25 second air pulses every 20 seconds to activate the material for a first-in, first out controlled flow.

Result

After initial testing, the AirSweep air pulse parameters were tweaked to resolve remaining hang-ups in the bin.

“The situation is much better than it was last year.”

The company also chose to install AirSweep to the other parts of the plant. For example, Kibble fines were being left behind in sloped transition approximately 4 inches above an airlock. They purchased AirSweep VA-06 304 stainless steel units, and the AirSweep team worked closely with them to find the correct mounting, pulse duration, air line size and pressure, and proper depth in the bin. “Initial results have been positive, and the AirSweep have been easily integrated into our automated cleanouts.”

In another set of bins, material bridging was setting off nuisance alarms triggered by low level sensors 10” (25.4 cm) above discharge flange. They installed AirSweep VA-12 units above the blockage area.