Solve Cement Flow Issues with AirSweep

Cement is an important building material with the global demand expected to reach 4.73 billion tons by 2025. However, many cement plants struggle to keep up with production because of bulk solid flow problems. Materials like limestone, slag, bauxite, gypsum, and clay are prone to bridging, ratholing, and flooding. Moisture—especially in Asia and other humid […]

See PostAirSweep Cuts Back on Cleaning Time

If you are looking to cut back on cleaning time then you need AirSweep. When you are cleaning your vessels, do you need to manually clean them, or flush them with flour or other materials? We have a better way to clean your vessels and save you time and money. An infant formula company produces […]

See PostThe Hidden Cost of Ineffective Material Flow Aids

Flow aids can resolve bridging, arching, and other material blocks, but many give limited results and come with hidden costs. So instead of solving the problem, they can even create new ones—and hinder productivity and revenue. Hammers and Manual Cleaning Hammers are the cheapest flow aid you can possibly find… or so you think. While […]

See PostDAZIC Zero Speed Switches Prevents Tons of Problems

What would happen if your conveyor system suddenly malfunctioned, and dumped all of your material on the ground? How long would it take you to clean it up? A cement manufacturer whose feeder loads up to 250 tons of gravel per hour knows that if a machine fails, any delay in response time means hours […]

See PostMeet Safety Regulations with DAZIC Zero Speed Switches

What could happen if one of your equipment malfunctions, and tons of material spill before you’re able to shut it off? The obvious problem would be the loss of production. You could spend hours, if not days, cleaning up the mess. You may even have to pull workers from other parts of the plant to […]

See PostAirSweep in the Mined Materials Industry

AirSweep is used in the mined materials industry. Nearly all manufacturing processes use mineral commodities. The smartphone you use every day (including its display and circuits) is made from at least 14 different mined materials. Unfortunately, mineral commodities are notoriously difficult to handle. They bridge, arch, and interlock. These material blocks can be as stubborn […]

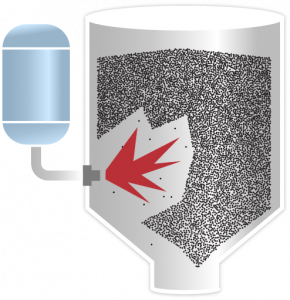

See PostAirSweep VS Air Cannon Management Style

Do you have an AirSweep or air cannon management style? The air cannon is like the obnoxious co-worker who’s really loud and loves to throw his weight around. But despite all its hot air, it makes a mess that somebody else has to clean up. AirSweep is the manager that quietly gets things done. It […]

See PostDAZIC: Mining and Processing of Mined Materials

Mined industrial materials are used to make thousands of commodities: building materials, electronics, detergents, medications, plastics, ceramics, paper, glass, and many more. Some minerals are used in processes — such as bentonite for gas and oil extraction, and kaolin for fracking operations. Many production facilities will process tons of mined materials a day. For example, […]

See PostHow to Reduce Material Handling Costs

Plants can manage tons of bulk powders and solids every month. In order to manage production costs, it is important to efficiently store, move, and process the materials without waste or delays. However, many materials have intrinsic properties that can affect how they react to the environment or flow in a vessel. Powders can settle […]

See PostAirSweep in the Food Industry

Product quality and safety are critical to the food industry. Product recalls can cause millions of dollars, permanently destroy brand reputation, and can even civil and criminal liabilities. Unfortunately, the rate of food recalls is increasing, and can be one of the biggest threats to a food company’s profitability, says Food & Safety Magazine. The […]

See Post