Material flow is the backbone of any successful operation in the mining and cement industries. Yet, common issues like bridging, ratholing, and material pileups can derail even the best-laid plans. These disruptions not only impact productivity but also drive up costs with additional labor and energy consumption.

The solution? AirSweep—a proven flow aid trusted by over 10,000 installations worldwide. Designed to handle the heavy-duty challenges of materials like clinker, fly ash, and copper concentrate, AirSweep ensures consistent material flow, minimizes downtime, and keeps operations running smoothly. Read on to discover why AirSweep outperforms traditional flow aids and how it’s revolutionizing bulk material handling in the cement and mining industries.

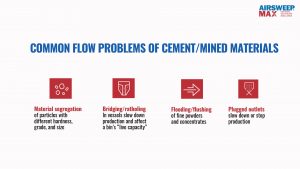

Common material flow problems in mining and cement

Heavy materials like clinker, fly ash, and copper concentrate pose significant challenges in processing plants. They often:

- Bridge or rathole inside vessels, reducing live capacity.

- Plug outlets, halting production lines.

- Segregate particles, disrupting material quality.

- Flood or flush fine powders, causing inefficiency and waste.

Traditional flow aids like vibrators, air cannons, and fluidizers are no match for such issues. They can compact materials, waste energy, or create safety risks by dispersing particles.

AirSweep flow aids solve the toughest flow problems of cement and mined materials.

Why AirSweep is the best flow aid for cement and mined materials

AirSweep releases high-pressure, high-volume, 360-degree pulses of compressed air that break through material blocks and clear vessel walls. It’s efficient, safe, and designed to tackle the toughest materials. It’s also more efficient, safe, and cost-effective than other flow aids.

- Fluidizers fail to activate heavy materials.

- Air cannons waste energy and spread material dangerously.

- Vibrators compact materials instead of clearing them.

AirSweep, on the other hand, activates materials quickly and completely, using less energy and plant air.

AirSweep is trusted by cement and mining companies worldwide

Built for Durability and Performance

AirSweep systems come with the longest warranty in the business—seven years—a testament to their reliability. Whether you need to clear stubborn clogs in silos or ensure smooth transport in trailers, AirSweep delivers unmatched performance.

Ready to revolutionize your operations? Contact the AirSweep team today to find out how we can optimize your material flow and prevent costly downtime.

Comments are closed