The Complete Guide to Flow Aids

Comments Off on The Complete Guide to Flow Aids

All industries need reliable material flow to maintain productivity and product integrity. Any material blocks–like settling of powders in storage, or material bridging in a hopper–cause delays and extra costs.

Unfortunately, most bulk materials will not flow properly without some kind of intervention. This complete guide to flow aids will tackle:

- What is a flow aid, and how does it improve plant operations

- The different kinds of flow aids, and their pros and cons

- What to consider when choosing a flow aid for your material and process

What are flow aids?

Flow aids are mechanisms or devices that encourage the efficient movement of materials inside a container or vessel. They prevent flow issues, such as:

- Sluggish flow. Some bulk solids like mined materials or liquid cheese will flow slowly because of their density or the tendency to interlock or cling to vessel walls. Flow aids activate the material and flush it out of the vessel.

- Material bridging in the hopper. Bridging, arching, or ratholing is a phenomenon where material forms an arch over the hopper outlet, thus obstructing the flow. Flow aids break up the bridges and prevent them from forming.

- Segregation. Mixes made of materials with different shapes, densities, or other physical or chemical properties can segregate during storage or even during processing. Flow aids can activate the material so that the flow (and the proportion of ingredients) remains constant.

What are the different kinds of flow aids?

There are three types of flow aids: mechanical, fluidizing systems, and chemical. Each has its pros and cons.

Mechanical flow aids use agitation or physical force to break up material blocks. Examples include vibrators, air knockers, paddle mixers, and agitators. Mechanical flow aids are relatively inexpensive and easy to source, they’re not appropriate for some vessels or materials.

Mechanical agitation causes metal fatigue, which can damage vessels–especially small vessels with thin walls. It can also make some materials more compact or cause heavier particles to settle. This can worsen material bridging in hopper or material segregation.

Fluidizing systems use air pulses to push material and break up cohesive friction. Examples include fluidizers, air pads, air cannons, and AirSweep.

While all of these use the principle of aeration, they are very different in terms of capability and operating cost.

Fluidizers and air pads use a combination of aeration and gentle vibration. These work on light powders like flour, but will not be effective for sticky, heavy, or moist materials.

Air cannons release more powerful blasts of air, but require more electricity and air to operate. They’re also big, bulky, and produce a lot of “kickback” so they may not be used on some types of process equipment.

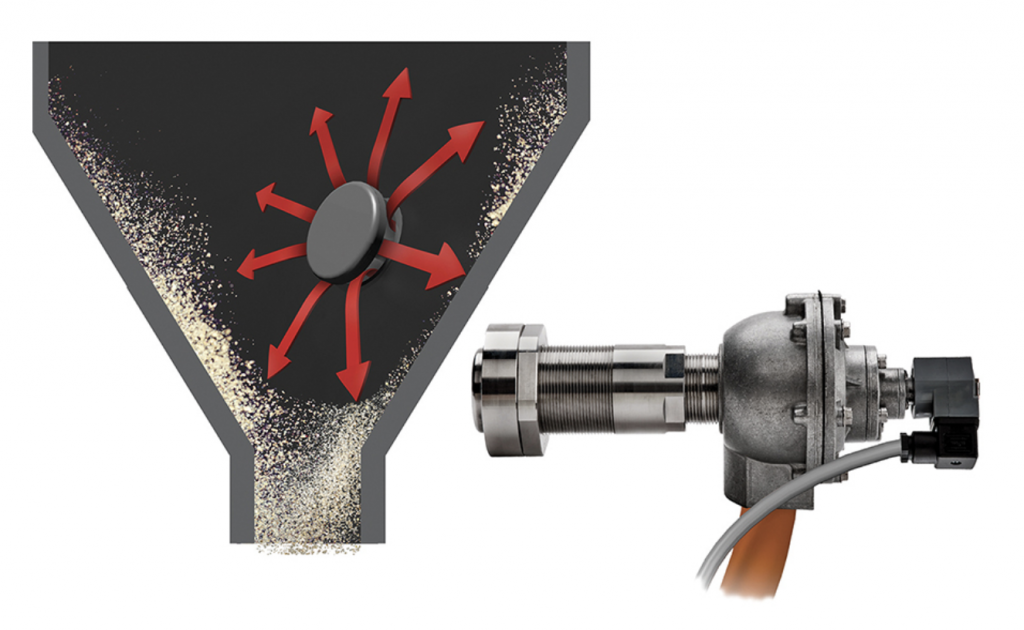

Among all the fluidizing systems, AirSweep is the best combination of performance, cost, and flexibility. It releases powerful, controlled air pulses that activate all types of material without damaging vessel walls. The compact nozzle can be installed on any vessel, including silos, hoppers, chutes, pipes, ribbon blenders, or any place where material tends to hang up.

Chemical flow aids change the material properties to material bridging in hoppers. For example, silicone-based agents like magnesium stearate can promote free flow, while anti-caking agents like calcium silicate can prevent lumps and caking.

While chemical flow aids can improve a material’s flow, they can’t break up material bridging in the hopper. Other flow aids must still be installed on the vessel itself to fix material blocks.

Questions to ask when choosing a flow aid

Like any other equipment investment, you need to consider different factors to find the best solution for your needs. Here is a checklist of key questions to ask while reviewing your options.

Material properties

- What materials have poor flow properties?

- What are the material’s other properties (density, cohesion, particle size, etc)

- How do they respond to moisture? Do they become wet or sticky?

- Do they tend to clump or settle during storage?

- How do they respond to vibration or aeration?

- Do any of the materials need sanitary handling to prevent spoilage or contamination?

Vessel characteristics

- What type of vessel do you have?

- What is the size of the vessel?

- Where is the vessel located?

- Where does the bridging or material flow problem usually occur?

- Do you have blind spots that are hard to reach?

Flow aid features

- What kind of materials can it activate?

- What is the activation radius?

- How much energy and air does it consume?

- Does it damage the vessel?

- Is it difficult to install? How long will installation take?

- Is it safe to use in hazardous environments?

- How often do I need to replace parts?

- How long will it take to receive replacement parts?

- Does it offer a warranty?

Worker experience

- Can it automate material flow, or will workers still need to monitor and manually clear material blocks and residue?

- How easy is it to clean and maintain the flow aid?

- Does it produce a lot of noise?

How to find the flow aid with the highest ROI

The right flow aid can solve material bridging in hoppers and other vessels and improve productivity and cost-efficiency. However, the wrong flow aid can actually increase delays and costs.

Learn more about how AirSweep can solve material flow problems and give the highest return on investment. You can watch this video or contact our sales team for a personalized consultation.

Safety and Production Issues? Signs You Need a Conveyor Belt Speed Sensor

Comments Off on Safety and Production Issues? Signs You Need a Conveyor Belt Speed Sensor

Barnes Concrete Co., a manufacturer of ready-mix concrete, handles tons of bulk material a day. They have 12 mixers, with feeders loading up to 250 tons of gravel an hour.

Any equipment malfunction would lead to an avalanche of bulk material which could injure workers and delay production for days. Plant supervisor Joe Kruzewski estimates it would take three people at least three hours to clear one ton. “It would be a train wreck [to be] buried with that amount of gravel.”

Fortunately, the concrete company never had an accident. Twenty years ago, they installed a conveyor belt speed sensor: DAZIC zero speed switch. It would signal whenever there was any abnormal change in the conveyor’s speed, so the team could quickly shut down the process before a pile-up occurred.

How does a conveyor belt speed sensor work?

A conveyor belt speed sensor measures the speed of a conveyor belt by detecting the rotation of one of the belt’s rollers or pulleys.

It is mounted on the shaft of the roller or pulley and generates an electrical signal as the shaft rotates. Then, it converts the signals into a speed measurement, typically expressed in revolutions per minute (RPM) or meters per second.

The DAZIC zero speed switch takes it a step further. Aside from measuring the speed, it sets off an alarm when RPM falls out of normal parameters.

For companies like Barnes Concrete Co., the DAZIC is a simple device that saves them a ton of problems. “It would be a nightmare if the DAZIC didn’t shut the conveyor belt down. I don’t even want to think about it,” Kruzewski said.

What are the benefits of a conveyor belt speed sensor?

Any manufacturing company can benefit from a DAZIC zero speed switch. It can:

- Prevent accidents like material spills and pile-ups

- Prevent bottlenecks by ensuring consistent equipment speed for synchronized processes

- Allow preventive maintenance by identifying potential equipment issues before they become serious problems

Signs you need a conveyor belt speed sensor

If you’re experiencing these issues in your plant operations, consider installing a DAZIC zero speed switch on your conveyors or any other equipment with a rotating shaft (bucket elevators, drive motors, saw blades, etc.)

- Frequent machine breakdowns. Changes in speed are often the first sign of other mechanical problems. A DAZIC zero-speed switch can detect these slowdowns in real-time so you can take corrective action, protecting your equipment from further damage.

- Safety concerns. Material pile-ups and spills are not the only safety issue when equipment runs at an inappropriate speed. It can lead to overheating, vibration, or other malfunctions which can cause accidents or even fires.

- Inefficient production line. When a machine slows down or stops unexpectedly, it can cause disruptions in the production line, affecting the overall workflow. A zero-speed switch enables you to fix the issue quickly to prevent bottlenecks and downtime.

Learn more about DAZIC

A DAZIC zero-speed switch can protect your equipment, improve productivity, and ensure a safer work environment. Contact us to find out more about DAZIC and how it can work in your process.

3 Ways AirSweep is Used in the Food Industry

Comments Off on 3 Ways AirSweep is Used in the Food Industry

Material handling efficiency is important for every industry, but it is especially important for companies that work with food and beverage, pharmaceuticals, nutraceuticals, and pet food.

These industries work with materials that can spoil and put millions of users at risk for poisoning and other health risks. They also need to make sure that materials are mixed in the right proportions, to preserve the flavor, consistency, and efficacy of their products.

That’s why some of the world’s biggest food manufacturers, as well as local businesses like bakeries and breweries, rely on AirSweep.

What is AirSweep?

AirSweep is a pneumatic flow aid that helps activate material through different stages of the production process. It releases timed, high-pressure air pulses that can break up clumps that form during storage, sweep material through hoppers and chutes during mixing, and flush vessels clean between batch runs.

Unlike other flow aids like vibrators or air cannons, AirSweep does not damage vessel walls or irritate workers with loud, relentless noise. It quietly activates even wet, sticky, or other problematic materials and gets the job done–without any need for manual intervention.

Since the AirSweep nozzles are programmed to release timed, controlled pulses in a strategic sequence–rather than running continuously–it is also more energy- and cost-efficient.

That’s why many manufacturers switched to AirSweep to achieve material handling efficiency. It provides reliable performance and solves common material flow problems with less cost.

Move difficult material with poor flow properties

The food industry often deals with materials that have poor flow properties, such as powdered ingredients, sticky substances, and granulated products. AirSweep’s powerful bursts of air can break up these materials and dislodge them from the sides of processing equipment, ensuring a smooth and consistent flow. This helps to reduce material waste, increase production throughput, and minimize the risk of costly stoppages.

Watch how AirSweep can work with liquid cheese – a particularly challenging material that is too heavy for fluidizers and will settle when vibrated with pneumatic hammers or industrial vibrators.

Flush vessels clean to shorten downtime and cleaning costs

Regular cleaning and maintenance of food processing equipment are crucial to prevent cross-contamination and ensure product quality. However, the cleaning process can be time-consuming and expensive.

An infant formula company was looking for a quick and reliable way to flush vessels clean between batch runs of regular and lactose-free products. However, they had to balance cost-efficiency with safety: even the slightest material residue could pose a significant health risk and lead to expensive product recalls.

AirSweep was the perfect solution. “We went from 40 hours to 10 hours in cleanup time,” said the Company’s Associate Director for Process Technology Application and Productivity. After the initial pilot test in one facility in 2016, they have since added AirSweep units to the other process lines in that plant, and in four other plants worldwide, and are currently adding the system to other plants.

Reduce material waste

Material handling efficiency also reduces waste because of spoiled material or out-of-spec batches. A commercial bakery that had issues with bridging and ratholing had to throw away up to 40 pounds of mixture a day and even had to pay to have it hauled away. As a local business with tight margins, this had a significant impact on their bottom line.

AirSweep was an affordable and cost-effective way to increase productivity and lower waste. They also appreciated the exceptional service and quick response times.

“Customer service has been very helpful. I would call with some ideas and they would work with me on it, and they were right! Installation was awesome and easy, and the units have saved the company a lot of man hours. My experience totally exceeded my expectations—a 10 out of 10!” said the maintenance department head.

Improve material handling efficiency with AirSweep

AirSweep offers numerous benefits to the food industry, from improving material flow to reducing cleaning time and ensuring product safety.

It can help companies face challenges such as increasing demand and stricter regulations, while streamlining their operations and costs without compromising safety.

Contact us to find out more about how AirSweep can help with your plant operations.

How to Improve Material Handling Safety: 7 Best Practices for a Safer Work Environment

Comments Off on How to Improve Material Handling Safety: 7 Best Practices for a Safer Work Environment

Material handling can present various safety challenges, including worker injury, exposure to toxic chemicals, flammable environments, and material spills. It’s important to implement safety protocols to prevent health hazards and meet industry regulations.

Read how to improve material handling safety in all plant operations.

Regular Training and Refresher Courses

Training is the bedrock of any safety protocol. All personnel involved in material handling should undergo a comprehensive training program and periodic refresher courses. This ensures that safety protocols remain top-of-mind and are updated with the industry’s best practices.

Limit Manual Handling

Even with the best techniques, the continuous manual handling of materials can lead to musculoskeletal disorders. Wherever possible, automate processes or use machinery.

For instance, a pneumatic flow aid like AirSweep can help move material through silos, hoppers, and other vessels. It prevents bridging and ratholing and eliminates the need for workers to manually clear material blocks with hammers or pick-axes.

Use of Personal Protective Equipment (PPE)

Wearing the right PPE can make a difference between a regular day at work and an unfortunate incident. Depending on the material and the nature of the job, PPE can range from safety gloves, hard hats, safety glasses, to steel-toed boots. Ensuring that the PPE is not just available, but also used correctly, is one of the best ways to improve material handling.

Safety protocols for heavy equipment

Forklifts, conveyors, and other heavy machinery play a significant role in material handling. However, they can also be sources of severe injuries if used incorrectly. Implement measures like designated walkways, clear signage, speed limits, and ensuring that only trained personnel operate such machinery.

Advanced safety features

Incorporate safety tools that monitor equipment and provide real-time feedback.

For instance, DAZIC zero speed switches can detect abnormal changes in speed of rotary equipment like conveyor belts or bucket elevators. If something goes wrong, these switches can trigger alarms or shut down the system, preventing material pile-up and worker injury.

Regular equipment maintenance

Well-maintained equipment is less likely to malfunction, thereby reducing the risk of accidents. Regular checks and preventive maintenance can catch potential problems before they escalate.

Emergency Preparedness

Despite the best precautions, emergencies can still occur. Prepare a well-documented and practiced emergency plan. Regularly conduct drills, ensure that emergency exits are clearly marked and unobstructed, and have first aid kits readily accessible.

Learn how to improve material handling with Control Concepts

Safety in material handling is a multi-faceted approach, from training and PPE to incorporating advanced systems like AirSweep flow aids and DAZIC zero speed switches.

We can help you ensure a safer work environment while also improving efficiency and productivity. Contact us to find out more about how to automate material handling and prevent material spills and pile-up.