DAZIC Zero Speed Switches Prevents Tons of Problems

Comments Off on DAZIC Zero Speed Switches Prevents Tons of ProblemsWhat would happen if your conveyor system suddenly malfunctioned, and dumped all of your material on the ground? How long would it take you to clean it up?

A cement manufacturer whose feeder loads up to 250 tons of gravel per hour knows that if a machine fails, any delay in response time means hours of backbreaking cleanup. Even just a 10-minute delay could result in 30 hours of downtime.

DAZIC Zero Speed Switches can help prevent material pileup and detect machine failure saving you time and money.

The cement manufacturer used DAZIC to prevent tons of problems. Their DAZIC solution costs less than $1,000 and hasn’t failed them once in the last decade. Read their story – and reach out to us if you’d like to have one installed in your plant.

Meet Safety Regulations with DAZIC Zero Speed Switches

Comments Off on Meet Safety Regulations with DAZIC Zero Speed Switches

What could happen if one of your equipment malfunctions, and tons of material spill before you’re able to shut it off?

The obvious problem would be the loss of production. You could spend hours, if not days, cleaning up the mess. You may even have to pull workers from other parts of the plant to get the job done faster or hire other people.

But the biggest and most expensive risk that you make is a violation of safety regulations.

- Can a worker be injured if he is buried under the material, or exposed to it?

- Does the material have hazardous properties? (Ex. can cause fires, chemical burns, health problems, etc.)

- Is the worker trained to personally handle and move the material? Does he know the proper safety precautions, and has he been given the proper safety equipment and gear?

- Is this part of his job description? Any task assigned to a worker outside of what he is trained to do increases the risk of injury.

The Occupational Safety and Health Administration (OSHA) has different levels of safety violations. However, the most serious violation is “When a business owner or manager knows there is a hazard that can result in injury or death and does nothing to resolve it.” Fines can reach up to $14,502 for each one, and willful or repeated violations can get stiffer penalties up to $145,207.

Use DAZIC Zero Speed Switches to Meet Safety Regulations

A DAZIC Zero Speed Switch can help prevent material pileups and detect machine failure. Just like fire alarms, they are cheap, easy to install, and can quickly alert you of a problem.

Speed switches are attached to any equipment that has rotating shafts. The sensors can detect if the rotations per minute (RPM) do not match the speed trip-points that you have set – either it is moving too fast, too slow, or stopped completely. It triggers an alarm and shuts it down.

Several plants around the world have installed DAZIC Zero Speed Switches to prevent worker injury and meet strict industry safety protocols.

Flammable Environments

Some fine powders can form explosive mixtures when released into the air, which can lead to flash fires. The Occupational Safety and Health Administration (OSHA) has classified these materials as combustible dusts.

Under OSHA regulations, companies that use these materials must have dust control measures that prevent the accumulation of the dust during daily operations, and an emergency action plan in case the dust collects or is accidentally dispersed.

One of the world’s largest rubber tire manufacturers uses carbon black—classified as a combustible dust—to improve durability and performance. They installed DAZIC Zero Speed Switches to prevent any material spills and meet OSHA safety standards.

Physical Injury

Some industries—like cement, mining, or minerals processing—work with very heavy bulk solids. If any of the equipment fails, workers would have to clear the material before production can resume. However, contact with any material outside of normal operations can have its own risks.

The type and level of hazards depend on the material properties and the process. However, scenarios can include:

- Physical injury from lifting heavy material, or being hit by debris

- Respiratory problems from inhalation of dust and fine powders

- Skin irritation, ranging from rashes to chemical burns

Knowing these risks, a ready-mix concrete manufacturer installed DAZIC Zero Speed Switches to prevent material pile-up. They have 12 mixers, with feeders that load up to 250 tons of gravel an hour.

While they are a local business with limited budgets, the DAZIC Zero Speed Switches were an inexpensive investment that has prevented workplace accidents and very expensive regulatory fines. “It’s really a safety issue,” said plant supervisor Joe Kruzewski. “It would be a train wreck [to be] buried with that amount of gravel.”

The DAZIC Zero Speed Switches are also very durable. The oldest one is 18 years old, and it is still working.

More Information

To learn more about how DAZIC works watch this video. Are you looking to meet safety regulations in your plant? Contact us and meet your safety regulations with DAZIC.

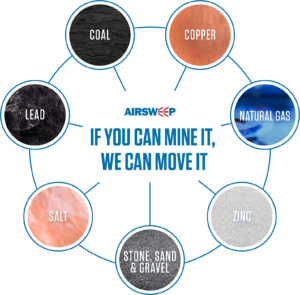

AirSweep in the Mined Materials Industry

Comments Off on AirSweep in the Mined Materials IndustryAirSweep is used in the mined materials industry. Nearly all manufacturing processes use mineral commodities. The smartphone you use every day (including its display and circuits) is made from at least 14 different mined materials.

Unfortunately, mineral commodities are notoriously difficult to handle. They bridge, arch, and interlock. These material blocks can be as stubborn as a rock—literally.

But AirSweep has solved this problem every single time. See it for yourself with the case studies and flow tests on our mined materials industry page. We work better than vibrators, bin activators, and air cannons on heavy materials. If that isn’t enough, AirSweep costs less to operate too!

What’s your toughest, most problematic flow problem? Contact us and we’ll find a way to fix it.

AirSweep VS Air Cannon Management Style

Comments Off on AirSweep VS Air Cannon Management StyleDo you have an AirSweep or air cannon management style? The air cannon is like the obnoxious co-worker who’s really loud and loves to throw his weight around. But despite all its hot air, it makes a mess that somebody else has to clean up.

AirSweep is the manager that quietly gets things done. It puts pressure where it’s needed, to keep things flowing and the process going. It reduces stress, and never leaves a mess.

You’ll see what we mean in our updated comparison between AirSweep and air cannons. Which one do you want to hire for your plant? (Referrals available upon request.)