Food/Agriculture

Materials Handled

Animal feeds

Brewer’s grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

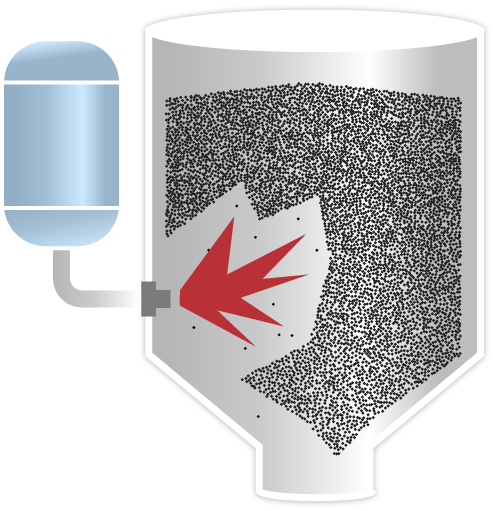

Industrial Air cannons are a pneumatic flow aid. In a typical application, air is compressed to 100 psi in a tank. When triggered, the valve opens and releases a high-magnitude blast that displaces stalled material.

Industrial Air cannons have a lot of power, but no control and limited results.

The nozzle extends into bin, so material can enter the system. The system needs frequent cleaning and costly replacements.

Industrial Air cannons uses (and wastes) high volumes of air. The peak force lasts only 1/1000th of a second – subsequent discharge is wasted energy.

Only suitable for vessels that can withstand high pressure. The strong recoil causes metal fatigue.

AirSweep works on all materials, and can be used for all vessels and applications

Animal feeds

Brewer’s grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

Aluminum

Bentonite

Coal

Copper

Diatomaceous earth

Gypsum

Iron ore

Limestone

Magnetite

Phosphate

Shale

Soda ash

Activated carbon

Adipic acid

Aluminum chloride

Boric acid

Chlorine

Herbicide

Hydrated lime

Iron oxide

Polyacrylamide

Titanium dioxide

Zinc

Acetate

Cement

Chalk

Cork

Detergent

Fertilizer

Fly ash

Pharmaceuticals

Plastics

Polymers

Resins sludge

Wax flakes

Wood chips

Companies saved time and money and got better results after switching from Industrial Air Cannons to AirSweep

Copyright Control Concepts, Inc. 2020, 19 S. Main Street, Brooklyn, CT 06234 • ph: 860-928-6551 • fax: 860-928-9450