Material handling efficiency is important for every industry, but it is especially important for companies that work with food and beverage, pharmaceuticals, nutraceuticals, and pet food.

These industries work with materials that can spoil and put millions of users at risk for poisoning and other health risks. They also need to make sure that materials are mixed in the right proportions, to preserve the flavor, consistency, and efficacy of their products.

That’s why some of the world’s biggest food manufacturers, as well as local businesses like bakeries and breweries, rely on AirSweep.

What is AirSweep?

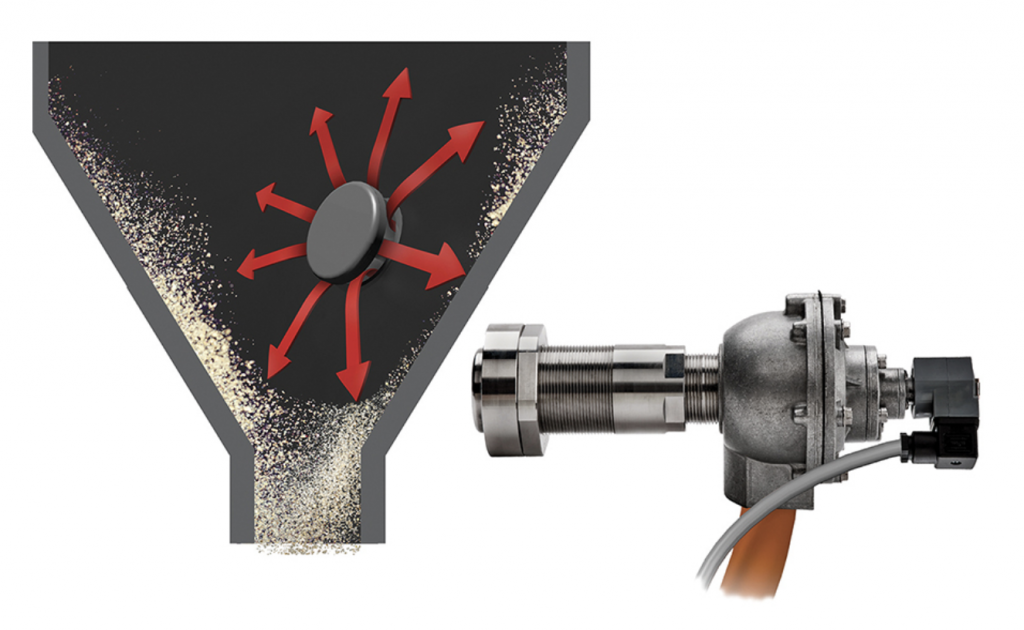

AirSweep is a pneumatic flow aid that helps activate material through different stages of the production process. It releases timed, high-pressure air pulses that can break up clumps that form during storage, sweep material through hoppers and chutes during mixing, and flush vessels clean between batch runs.

Unlike other flow aids like vibrators or air cannons, AirSweep does not damage vessel walls or irritate workers with loud, relentless noise. It quietly activates even wet, sticky, or other problematic materials and gets the job done–without any need for manual intervention.

Since the AirSweep nozzles are programmed to release timed, controlled pulses in a strategic sequence–rather than running continuously–it is also more energy- and cost-efficient.

That’s why many manufacturers switched to AirSweep to achieve material handling efficiency. It provides reliable performance and solves common material flow problems with less cost.

Move difficult material with poor flow properties

The food industry often deals with materials that have poor flow properties, such as powdered ingredients, sticky substances, and granulated products. AirSweep’s powerful bursts of air can break up these materials and dislodge them from the sides of processing equipment, ensuring a smooth and consistent flow. This helps to reduce material waste, increase production throughput, and minimize the risk of costly stoppages.

Watch how AirSweep can work with liquid cheese – a particularly challenging material that is too heavy for fluidizers and will settle when vibrated with pneumatic hammers or industrial vibrators.

Flush vessels clean to shorten downtime and cleaning costs

Regular cleaning and maintenance of food processing equipment are crucial to prevent cross-contamination and ensure product quality. However, the cleaning process can be time-consuming and expensive.

An infant formula company was looking for a quick and reliable way to flush vessels clean between batch runs of regular and lactose-free products. However, they had to balance cost-efficiency with safety: even the slightest material residue could pose a significant health risk and lead to expensive product recalls.

AirSweep was the perfect solution. “We went from 40 hours to 10 hours in cleanup time,” said the Company’s Associate Director for Process Technology Application and Productivity. After the initial pilot test in one facility in 2016, they have since added AirSweep units to the other process lines in that plant, and in four other plants worldwide, and are currently adding the system to other plants.

Reduce material waste

Material handling efficiency also reduces waste because of spoiled material or out-of-spec batches. A commercial bakery that had issues with bridging and ratholing had to throw away up to 40 pounds of mixture a day and even had to pay to have it hauled away. As a local business with tight margins, this had a significant impact on their bottom line.

AirSweep was an affordable and cost-effective way to increase productivity and lower waste. They also appreciated the exceptional service and quick response times.

“Customer service has been very helpful. I would call with some ideas and they would work with me on it, and they were right! Installation was awesome and easy, and the units have saved the company a lot of man hours. My experience totally exceeded my expectations—a 10 out of 10!” said the maintenance department head.

Improve material handling efficiency with AirSweep

AirSweep offers numerous benefits to the food industry, from improving material flow to reducing cleaning time and ensuring product safety.

It can help companies face challenges such as increasing demand and stricter regulations, while streamlining their operations and costs without compromising safety.

Contact us to find out more about how AirSweep can help with your plant operations.

Comments are closed