Wheat Gluten Powder Material Flow Test

Comments Off on Wheat Gluten Powder Material Flow TestWheat gluten is used in many industries: food and beverage, health and personal care products, pharmaceuticals and animal feeds.

Wheat gluten has good water retention and texture stabilizing properties. It is often added to low-gluten or whole grain flours like rye or oat, or to food products like instant noodles. Because of the vitamins and minerals in wheat, it is also added to animal feed and skincare products.

However, wheat gluten can be prone to bridging, arching and other material flow problems. This video shows how it clogs up the mouth of the vessel, and has to be hammered free.

However, AirSweep pneumatic flow aids are particularly effective for these types of bulk powders. Four AirSweep VA-04 units were installed 4” and 10” above the discharge, and spaced 90 degrees apart. Once they were turned on, the wheat gluten powder flowed freely, even when the discharge size was shortened from 4” to 1.5”

AirSweep also has USDA-accepted models that meet the sanitary requirements of food and pharmaceutical industries. The air-tight nozzle also eliminates material feedback, so none of the powders fly back into the nozzle. This minimizes cleaning and maintenance, and prevents damage to the system.

While the AirSweep VA-06 units are meant for smaller vessels, there are models available for large silos, bins and cones.

USDA AirSweep: Simple, Sanitary Solution for Material Blocks

Comments Off on USDA AirSweep: Simple, Sanitary Solution for Material BlocksThe USDA-accepted AirSweep delivers powerful material activation and vessel cleaning performance, all in a design specifically made and approved for sanitary bulk material handling processes.

Its features include:

- Air-tight design that guards against material retention and bacterial growth

- Modular construction for easy cleaning and inspection

- Tri-flange mount for tool-less removal

Watch the video to find out how the USDA-accepted AirSweep works, how to remove it for cleaning, possible applications, and the benefits to your business.

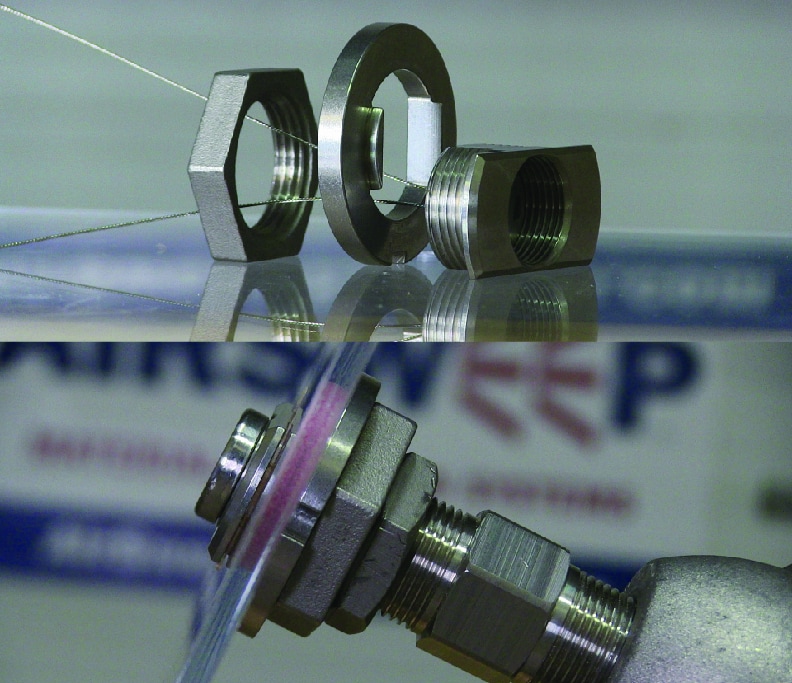

How to Install the AirSweep: Proper Nozzle Alignment

Comments Off on How to Install the AirSweep: Proper Nozzle AlignmentThe AirSweep® nozzle is installed outside the vessel by cutting a small hole and welding a threaded mounting coupling in place. The nozzle is then threaded into the coupling and positioned inside the vessel at a depth that allows the air flow to sweep closely along the inside walls. A lock nut holds the nozzle in place once it is properly aligned.

In this video, we show how to install the Airsweep nozzle to proper depth in a vessel.

Peanut Dust Material Flow Test

Comments Off on Peanut Dust Material Flow TestMany food ingredients such as peanuts can be prone to flow issues: arching, ratholing, caking, and clinging to vessel walls. These can lead to production delays and product losses, affect batch uniformity, and cause issues like cross-contamination or spoilage.

AirSweep material activation systems can help promote on-demand flow of peanut products and other food ingredients. The AirSweep® USDA-accepted models are also designed to meet strict sanitation standards, further protecting product quality and safety.

AirSweep vs Fluidizers: Spanish Subtitles

Comments Off on AirSweep vs Fluidizers: Spanish Subtitles“What is the difference between AirSweep and other pneumatic flow aids?” In this video, Paul the AirSweep guy gives a simple, straightforward answer. He compares the AirSweep with the rubber fluidizing disc, and then shows the difference in a material activation test.

Since the AirSweep® is used in every region, this video provides Spanish subtitles. Visit our Resources section to download brochures and data sheets in Spanish.

Organic Natural Fiber Blend (Ultrafine) Material Flow Test

Comments Off on Organic Natural Fiber Blend (Ultrafine) Material Flow TestNatural fibers are used to make fabric, construction and insulation materials, and packaging. While they are a cost-effective, environmentally-friendly material, they are prone to arching, bridging and ratholing issues. AirSweep can cut through material blocks to promote smooth, on-demand flow. It can be used with any form of natural fibers, including LCF blends or raw LCF. Watch the material flow test to see AirSweep’s power and efficiency.

Chopped Tobacco Material Flow Test

Comments Off on Chopped Tobacco Material Flow TestAirSweep® pneumatic flow aids are ideal for promoting the flow of irregularly-shaped, dry and light bulk solids. These include chips, fibers, flakes, and shavings. This material flow test shows how the AirSweep® VA-06 model works on chopped tobacco.

The AirSweep® VA-06 model is ideal for small bins, hoppers, chutes, and mixers. It activates up to 3 feet diameter of material. Other units are available for larger vessels.

Cheerios Material Flow Test

Comments Off on Cheerios Material Flow TestIn this Cheerios material flow test, you can see how AirSweep promotes on-demand flow even in imperfect conditions. The plant humidity levels can cause cereal (or similar materials) to clump and stick together, and the vessel outlets are narrowed. However, a few pulses of AirSweep completely clear the vessels without crushing the cereal.

How to Install the AirSweep: Outside-In Mounting Bracket

Comments Off on How to Install the AirSweep: Outside-In Mounting BracketOutside-Inside mounting kit includes all parts to easily install the Airsweep material flow system in any vessel without welding.

Unlike many other flow aids, AirSweep® material activation system is installed outside the vessel for easy installation, cleaning and maintenance. AirSweep Outside-Inside (O-I) mounting brackets allow for easy, no-weld mounting of the AirSweep material flow system nozzles from the exterior of the process vessel or equipment.

Installation is fast, easy and inexpensive. The innovative outside-in mounting bracket does not need any welding—all you need is a 1-3/8″ diameter hole and a spanner wrench. Just follow this simple AirSweep installation video tutorial.

Using the supplied mounting kit, O-I brackets install by inserting through the outside wall of the equipment and bolting into place. Holes from previously installed equipment may be used, often with little or no modification. Once the bracket is in place, the Airsweep nozzles can be simply threaded into place, to provide on-demand flow of the toughest materials. The O-I mounting brackets are available in three sizes, to accommodate the models VA-06, VA-12 and VA-51 Airsweeps.

With the AirSweep Outside-In Mounting Bracket, you can retrofit or replace existing aeration devices with minimal cost or delays. You can also find more detailed installation and maintenance guides for your AirSweep model in our Resources section.

DAZIC Zero Speed Switch: Prevent Material Pileup

Comments Off on DAZIC Zero Speed Switch: Prevent Material PileupIndustrial processes and systems use many interconnected moving parts. If any of those parts failed unexpectedly, it can create a cascading effect that can damage products, equipment and infrastructure and create safety hazards. DAZIC zero speed switches can help prevent costly and dangerous material pileups.

What is DAZIC®?

DAZIC® stands for Direction and Zero Indicating Contactors. It can be integrated into your system and alert you when the device rotation deviates from its standard operating parameters.

DAZIC can be installed on any device with a rotating shaft. This includes:

- Rotary valves

- Bucket elevators

- Belt and screw conveyors

- Saw blades

- Drive motors

What are the different DAZIC models?

Choose from our three lines of electromechanical, inductive, and electronic zero speed switches. The video discusses the different products and their features, to help you decide which model is best suited for your needs.

Electromechanical series

- No electrical input needed

- Base or flounge mount

- Can be connected to shaft, pulley, wheel, chain sprocket and more

- Wide range of models for all applications

- Durable housing options include aluminum, cast iron, and explosion-proof

Electronic Rotoguard IV Series

This DAZIC line transforms the rotation of the input shaft to voltage pulses, which are then digital processed to detect changes in motion or application up to 400 RPM. It is designed to withstand tough environments.

- Solid state electronics

- Base or flange mount

- Universal voltage input

- Programmable start up and alarm delay

- Simple push button calibration

- NEMA 4 or explosion-proof housings

Prox Micro Inductive Proximity Switch

The DAZIC non-contact micro-sensing device precisely monitors the RPM rate of many rotating ferrous target.

- Large sensing range

- Easy to program and field adjustible

- Status and relay indicating LEDs

- Non-contact sensing, does not connect to shaft

- Reads any ferrous target

- Powder-coated NEMA 4 aluminum housing for long life and tough industrial applications

Trusted by the world’s biggest brands

All DAZIC products are manually assembled and tested to ensure their quality and reliability. It is trusted by DuPOnt, Covanta, Starbucks, Cooper Tires, Jack Daniel’s, AK Steel, GoodYear, the city of Spokane, and more. Watch the video for more information about zero speed switches.