AirSweep Material Flow Aid receives ATEX certification for explosive environments

Leave a Comment

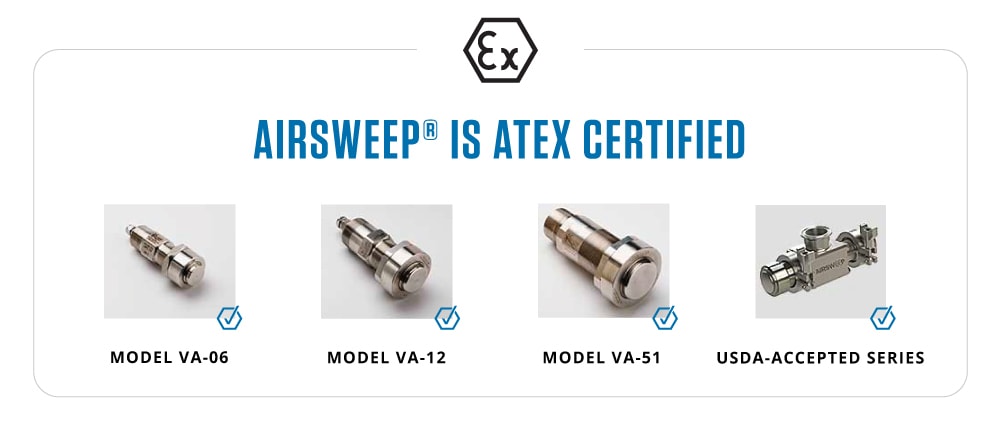

Control Concepts, Inc. announced that all AirSweep® pneumatic flow aids have been awarded an ATEX certification, based on the assessment of the FTZU Physical-Technical Testing Institute in the Czech Republic.

ATEX (which stands for ATmosphères EXplosibles) is required for all products that are used in explosive environments in the European Union.

An explosive atmosphere can be caused by a variety of substances and chemicals in the air, such as flammable gases, mists or vapours, or fine organic dusts like grain flour or wood. This includes petrochemical industries, underground mining and food production.

“AirSweep is used heavily in these kinds of environments,” says Henry Tiffany, president of Control Concepts, Inc. “It will also help our EU distributors sell our products, because many of their customers require it for their specific applications.”

The ATEX certification assures customers that AirSweep – the most effective material flow aid for powders, bulk solids, granular materials, moist or sticky materials and more – has been fully tested and approved to be safe to use in hazardous environments.

About Control Concepts, Inc.

Since 1951, Control Concepts, Inc. has helped solve material flow issues in plants around the world. We have tens of thousands of systems installed worldwide, and clients that include both S&P companies and SMEs. Our patented technologies are used in every industry because they are reliable, cost-effective, and have an amazing track record and return on investment. We also have the longest warranties in the industry.

When you install a ControI Concepts product, you can walk away and focus on other parts of the plant. Our AirSweep® material activation system ensures on-demand material flow, AcoustiClean® Sonic Horns replaces manual material clearing, and DAZIC® and RotoGuard® Speed Switches prevent expensive equipment pileup.