Food/Agriculture

Materials Handled

Animal feeds

Brewers grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

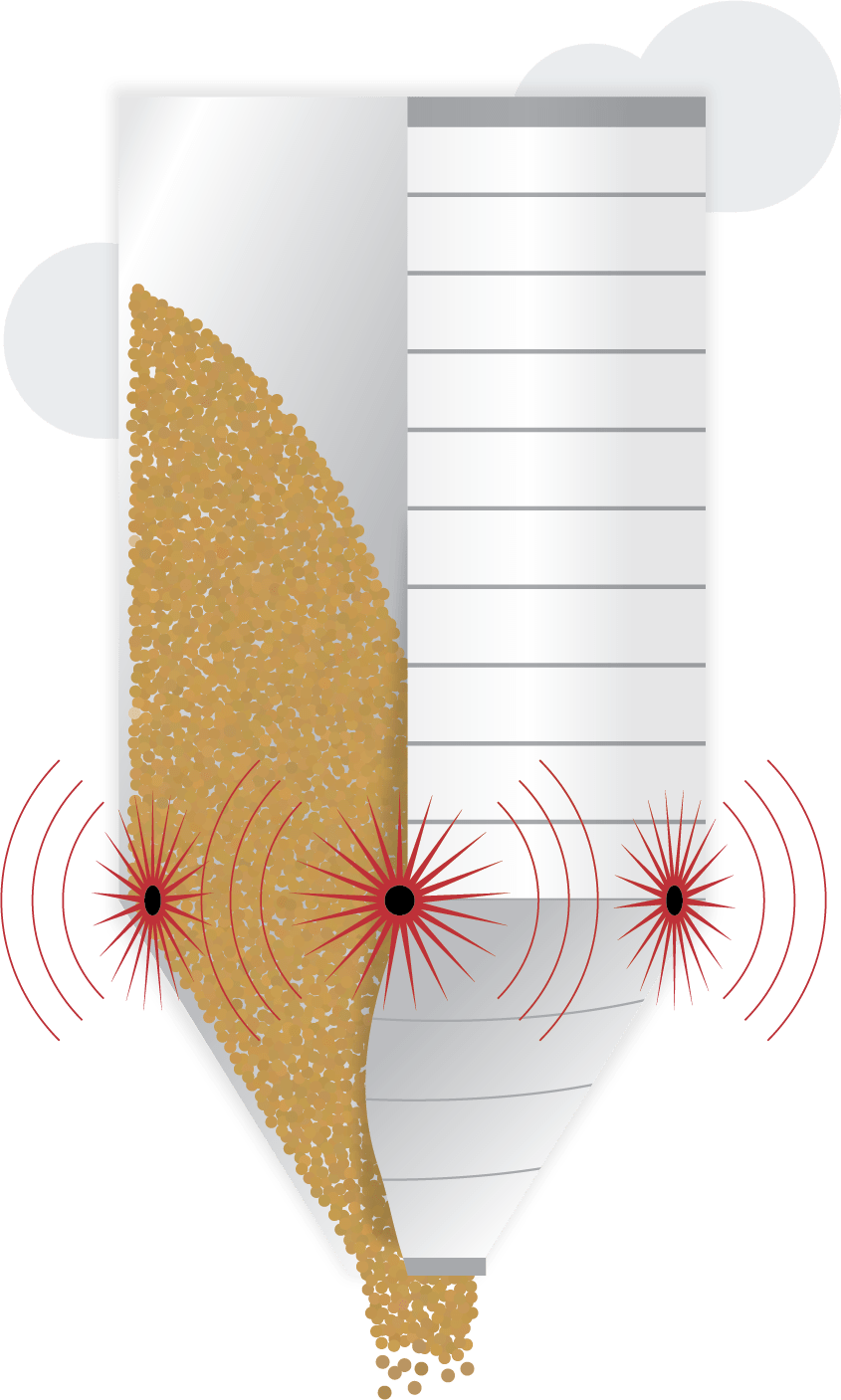

Industrial vibrators use vibration or mechanical agitation to improve material flow. It’s the same principle behind shaking a ketchup bottle: the movement breaks apart the material and loosens it from the vessel walls.

Industrial vibrators can be installed on silos, bins and hoppers to prevent bridging, arching and other material blocks.

Other uses include:

Hydraulic vibrators use compressed fluid to generate enough mechanical energy to rotate a shaft. Pneumatic vibrators work the same way, but use compressed air. Sometimes, it activates an object (like a ball, roller or piston). Electric vibrators are simply plugged in.

Industrial vibrators can also be classified according to the area of activation. For example, rotary pneumatic vibrators send out circular vibrations, while impactors are like “automatic hammers” that direct force at a specific area.

These vibrators all have their pros and cons. Generally, hydraulic vibrators are used for heavy-duty jobs in wet or dusty environments. Pneumatic vibrators are used for fine powders, while electric vibrators are thought to be the quietest of the three.

While industrial vibrators are effective for some processes, they may not always be the best flow aid for wet or sticky materials. Just like the ketchup bottle, there will always be some residue left, no matter how much you shake it.

In some cases, industrial vibrators can also cause or worsen blocks because they end up compacting the material. Read the first-hand experience of some plant managers who installed vibrators on their vessels.

Industrial vibrators also cause metal fatigue, and the continuous noise can add to worker stress. As one plant manager put it, “it’s like fingernails on a chalkboard—you just want to get away from it.”

Animal feeds

Brewers grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

Aluminum

Bentonite

Coal

Copper

Diatomaceous earth

Gypsum

Iron ore

Limestone

Magnetite

Phosphate

Shale

Soda ash

Activated carbon

Adipic acid

Aluminum chloride

Boric acid

Chlorine

Herbicide

Hydrated lime

Iron oxide

Polyacrylamide

Titanium dioxide

Zinc

Acetate

Cement

Chalk

Cork

Detergent

Fertilizer

Fly ash

Pharmaceuticals

Plastics

Polymers

Resins

Sludge

Wax flakes

Wood chips

Where industrial vibrators have failed, Airsweep has succeeded. Check out the brief infographics below.

An AirSweep® system will pay for itself, in as little as two weeks with:

Control Concepts, Inc. provides a

7-year warranty on the Airsweep® unit.

Copyright Control Concepts, Inc. , 19 S. Main Street, Brooklyn, CT 06234 • ph: 860-928-6551 • fax: 860-928-9450