Food/Agriculture

Materials Handled

Animal feeds

Brewer’s grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

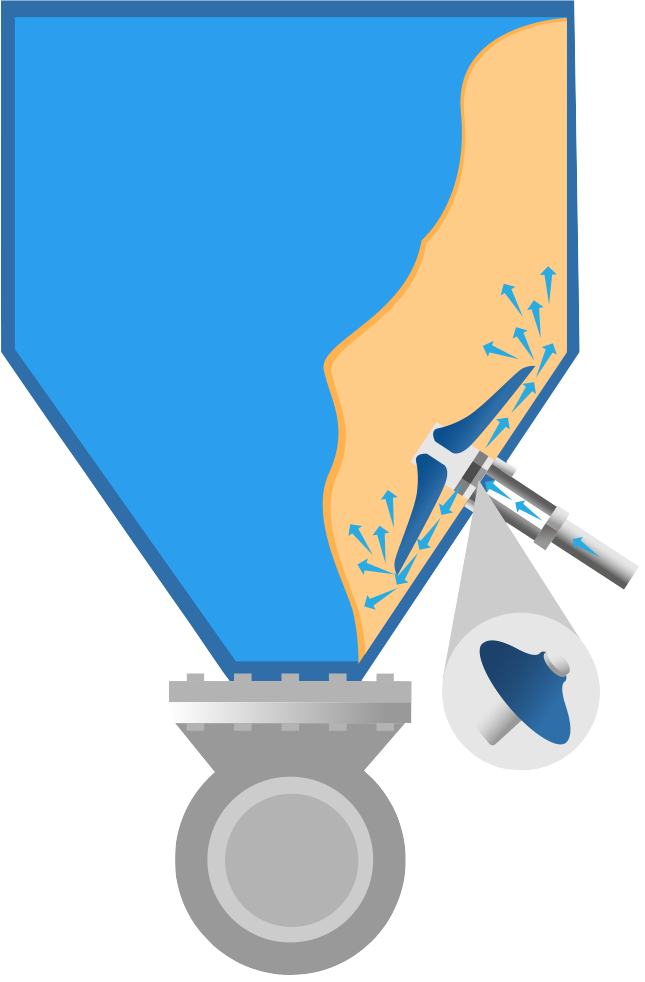

Fluidizers are a pneumatic flow aid that use a combination of aeration and gentle vibration to promote material flow. The discs force air to move along the vessel wall, which loosens the material and prevents it from plugging or becoming compact.

Fluidizers are often used in storage silos, hoppers, and dust control systems. They can be installed outside or inside the vessel, and are usually made of silicone or EPDM rubber.

Fluidizers work best with dry bulk materials that respond to gentle aeration, or have a moisture content that is less than 12 to 15 percent. There are models designed for either low-pressure/high-volume and high-pressure/low-volume air, but they generally have less power and a smaller activation radius than other flow aids.

Fluidizers are used to prevent ratholing and bridging in silos and other storage containers, or to promote discharge from transportation like dry bulk trailers.

Fluidizers are inexpensive and easy to install, since they only require a small hole for the discs. Some vessels already come with pre-fitted fluidizing systems.

But while the initial costs are low, fluidizers may not be as cost-effective as they seem.

Limited activation radius. You may need more units to achieve the desired results.

Limited activation radius. You may need more units to achieve the desired results.  Frequent replacement. They degrade quickly. Even slightly uneven edges can lead to inconsistent airflow or affect its ability to seal tightly against the vessel walls. In these cases, the fluidizers must be replaced.

Frequent replacement. They degrade quickly. Even slightly uneven edges can lead to inconsistent airflow or affect its ability to seal tightly against the vessel walls. In these cases, the fluidizers must be replaced.  Frequent visual inspections and cleaning. Material can cake or harden underneath the discs.

Frequent visual inspections and cleaning. Material can cake or harden underneath the discs. Ineffective for some materials. Fluidizers can only activate dry powders or light solids. They can’t be used for large particles like gravel, interlocking particles like wood shavings or fiberglass, or moist or dense material like whey.

Ineffective for some materials. Fluidizers can only activate dry powders or light solids. They can’t be used for large particles like gravel, interlocking particles like wood shavings or fiberglass, or moist or dense material like whey.  |

Fluidizers |

|

|---|---|---|

| Functionality | High-pressure, high-volume air pulses lift stalled material back into the flow stream. | Air causes the rubber disks to flap and vibrate, activating material with a combination of gentle vibration and aeration. |

| Activation Radius | One nozzle can stimulate up to 2.44m (8 ft.) diameter circle of material | Small, clean radius. You may need to install many units to achieve adequate coverage. |

| Maintenance Costs | No damage, vibration, stress or wear to vessel walls

Only needs inspection every 6 months, and replacement of parts after 1,000,000 cycles Uses 10 cfm of compressed air or gas |

May cause vessel wall abrasion

System accessories like hoses, valves, and regulators incur additional hidden costs High energy consumption |

| Sanitation | Only the nozzle tip comes in direct contact with material

USDA-accepted models available |

Disc material may degrade, contaminating the product

Not the best solution for food or abrasive materials. |

| Worker Safety and Convenience | Reduces workload: can be used to provide on-demand flow or automatic cleaning/flushing of vessels

Parts can be inspected and removed without tools for quick, easy cleaning |

Can present safety issues if workers have to access the inside of the vessel to install or maintain them |

| Noise Levels | Makes a quick, ear-friendly “psst” or “pop” | Can be noisy |

| Material Control | Effective for all materials, including moist, sticky, and heavy powders and bulk solids | Only effective for light powders like flour |

AirSweep works on almost any kind of material—from fine powders to moist, sticky or wet bulk solids.

Animal feeds

Brewer’s grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

Aluminum

Bentonite

Coal

Copper

Diatomaceous earth

Gypsum

Iron ore

Limestone

Magnetite

Phosphate

Shale

Soda ash

Activated carbon

Adipic acid

Aluminum chloride

Boric acid

Chlorine

Herbicide

Hydrated lime

Iron oxide

Polyacrylamide

Titanium dioxide

Zinc

Acetate

Cement

Chalk

Cork

Detergent

Fertilizer

Fly ash

Pharmaceuticals

Plastics

Polymers

Resins sludge

Wax flakes

Wood chips

Many plants that used fluidizers for these materials had to resort to manual cleaning. Eventually, they would shift to more powerful pneumatic flow aids like AirSweep.

An AirSweep® system will pay for itself, in as little as two weeks with:

Control Concepts, Inc. provides a

7-year warranty on the Airsweep® unit.

Copyright Control Concepts, Inc. , 19 S. Main Street, Brooklyn, CT 06234 • ph: 860-928-6551 • fax: 860-928-9450