Air Knockers vs AirSweep:

Pros and Cons

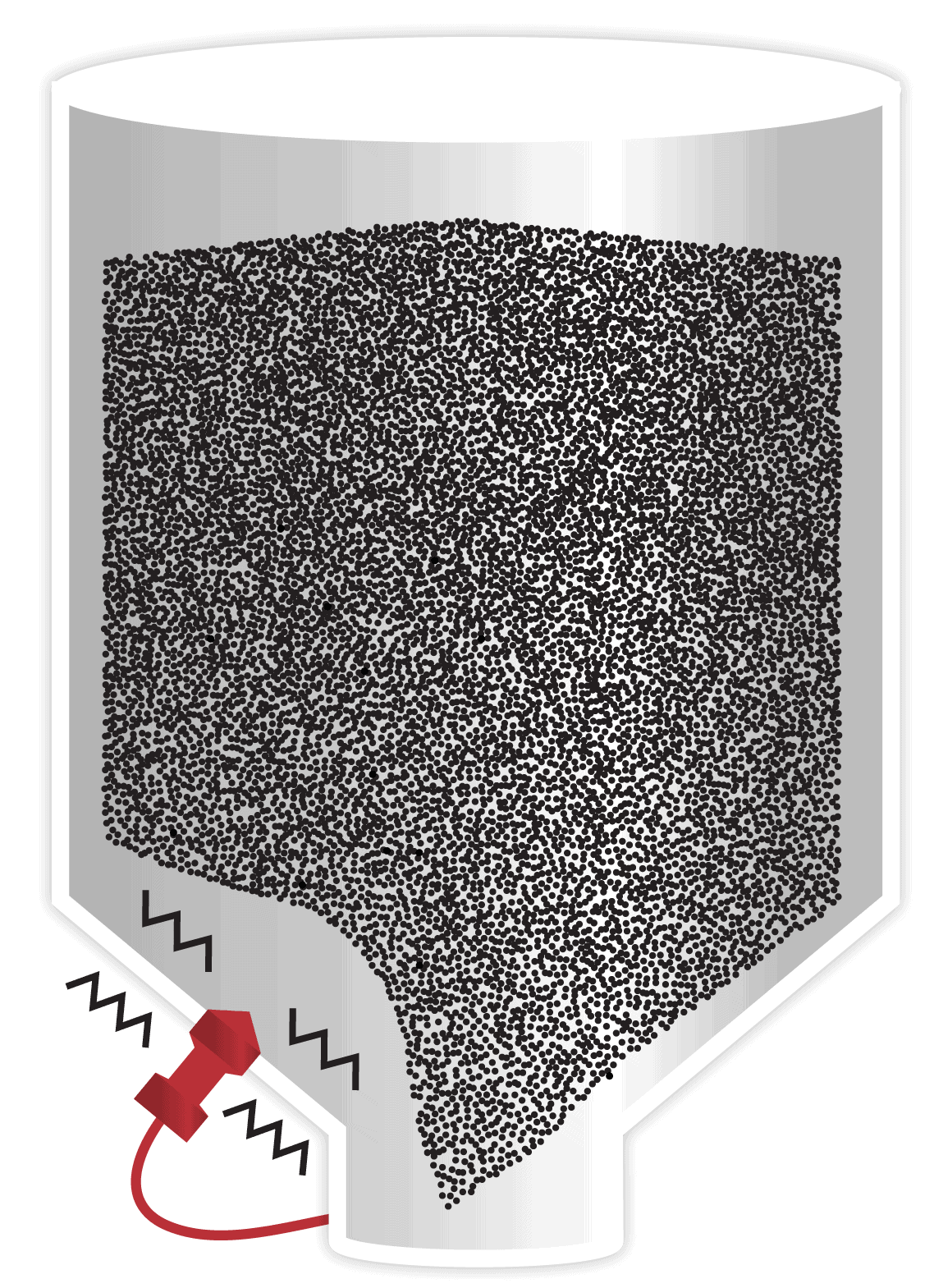

Air knockers are like pneumatic hammers.

Compressed air pushes the piston against the vessel wall and makes it vibrate. The shaking and agitation loosen material that cling to the vessel walls.

Air knockers (or air hammers) are used to:

- Shake off excess powder

- Remove products from molds

- Remove water and splatter

- Prevent adhesion of workpieces

AIR KNOCKERS VS AIRSWEEP

Air Knocker

AIRSWEEP®

Functionality

Air Knocker

- Air knockers induce vibration energy to the vessel wall, which transmits into the material to shake it loose

AIRSWEEP®

- Directs smaller, equally powerful bursts of air along the bin wall, lifting material off the wall and back into the flow stream

- Eliminates bridging, ratholing, or sticking problems

- Stimulates up to a 2.44 m (8 foot) diameter circle of material around each nozzle

Noise Level

Air Knocker

- Air knockers can be extremely noisy

AIRSWEEP®

- Makes a quick, ear-friendly “psst” or “pop”

Maintenance

Air Knocker

- Metal and weld fatigue can occur due to vibration or hammering from piston air knocker. Wear and tear on vessel walls can be costly

- Expensive to operate. Air knockers use a lot of air or power to operate

AIRSWEEP®

- No damage, vibration, stress or wear to vessel walls

- Uses as little as 10 CFM of compressed air or gas

- Only needs inspection every 6 months, and replacement of parts after 1,000,000 cycles

- Longest industry warranty – 7 years

Material Control

Air Knocker

- Sticky material remains, and builds up over time on bin walls, even if bridging is controlled

- Periodic shutdowns may still be required to clean bin walls, especially if cross-contamination is an issue

AIRSWEEP®

- Each pulse of the AirSweep sweeps along the bin walls, preventing material from adhering to the sides, or building up

- In general, full clean out of the bin occurs with each batch, ensuring first-in/first-out material flow with no cross-contamination

Are You Just Getting a More Expensive Hammer?

AIR KNOCKERS ARE NOT EFFICIENT FLOW AIDS

POOR MATERIAL CONTROL

- Not effictive for all materials

- Sticky residue can remain on walls

- Does not promote first in/first out flow

EXPENSIVE

- Metal fatigue damages the vessels

- Uses a lot of plant air and electricity

INCONVENIENT

- Causes worker stress and can affect hearing

- Vessels still require periodic manual cleaning

- Highest ROI. AirSweep can help you boost productivity, lower your energy and maintenance costs, and save on manpower.

- Low maintenance. You only need to replace parts after 1,000,000 cycles.

- Longest warranty.

Control Concepts, Inc. provides a

7-year warranty on the Airsweep® unit.

7-year warranty on the Airsweep® unit.

Ask us about our money-back guarantee and ROI calculation

Copyright Control Concepts, Inc. 2020, 19 S. Main Street, Brooklyn, CT 06234 • ph: 860-928-6551 • fax: 860-928-9450