Food/Agriculture

Bulk Materials Handled

Animal feeds

Brewers grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

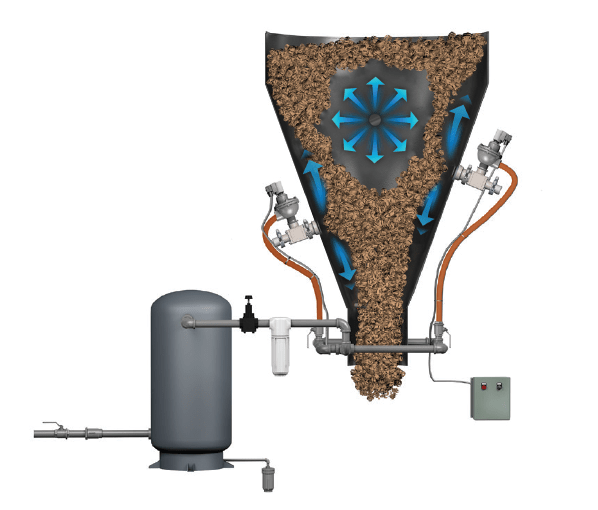

The new AirSweep maximizes your productivity, speed and cost-efficiency. Each pulse generates stronger force and free-flowing air stream that activates more material with less energy and plant air.

Laboratory tests proved that AirSweep MAX delivers 52% more output pressure.

FASTER MATERIAL FLOW

Quickly empty the vessel for higher production or shorter cleaning times.

LOWER OPERATING COSTS

Use less energy and plant air to activate the same amount of material.

20 aerospace-grade design specs | 20 patented improvements | 6 proprietary parts

AirSweep MAX’s performance is a result of its proprietary design and parts.

You can’t copy quality.

Animal feeds

Brewers grain

Cocoa

Coffee

Corn

Flour

Grains

Hops

Salt

Soybeans

Spices

Starches

Sugar

Aluminum

Bentonite

Coal

Copper

Diatomaceous earth

Gypsum

Iron ore

Limestone

Magnetite

Phosphate

Shale

Soda Ash

Activated carbon

Adipic acid

Aluminum chloride

Boric acid

Chlorine

Herbicide

Hydrated lime

Iron Oxide

Polyacrylamide

Titanium dioxide

Zinc

Acetate

Cement

Chalk

Cork

Detergent

Fertilizer

Fly ash

Pharmaceuticals

Plastics

Polymers

Resins sludge

Wax flakes

Wood chips

|

Vibrators |

Fluidizers |

|

|---|---|---|---|

| Technique | Uses pulses of pressurized air | Uses vibration to shake material free | Air flows into a disc, which flaps and vibrates |

| Activation Radius | Effective radius of 4 feet | No specific activation area | Small activation radius |

| Material Control | Can be used with dry, wet, or sticky materials | Sticky material still builds up, even if bridging is controlled | Not good with sticky or wet materials |

| Noise | Emits quiet hiss with each pulse | Extremely noisy | Noisy – sounds like air horn when operating |

| Damage to Product or Vessel | No container fatigue; can be used on thin-skinned bins | Metal and weld fatigue from vibration or hammering of piston air knocker | May cause vessel abrasion; disc material can degrade and contaminate product |

| Cost of Operation | Intermittent pulsing – only a small amount of plant air | Longer period of operation uses more air and power | Longer period of operation uses more compressed air |

| Installation | Installed from outside vessel, for easy cleaning and maintenance | Installed from outside – channel iron required for reinforcement and transmission | Installed inside the vessel |

Control Concepts, Inc. provides a

7-year warranty on the Airsweep® unit.

AirSweep units have ATEX product Certification (or EU-Type Examination)

Copyright Control Concepts, Inc. , 19 S. Main Street, Brooklyn, CT 06234 • ph: 860-928-6551 • fax: 860-928-9450